Enhancing CO2 Injectivity in High-Salinity and Low-Permeability Aquifers: A Case Study of Jianghan Basin, China

-

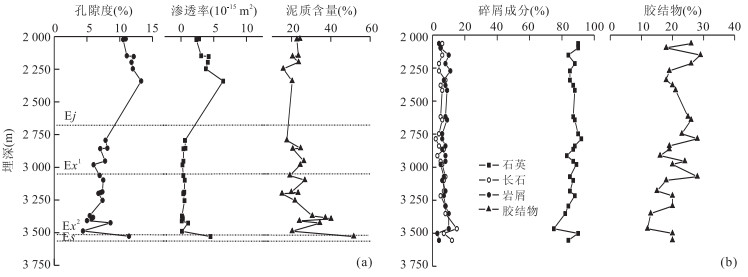

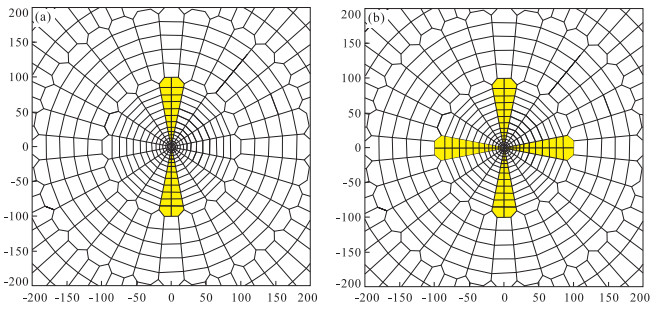

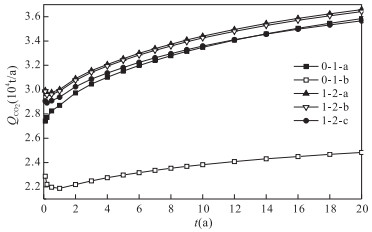

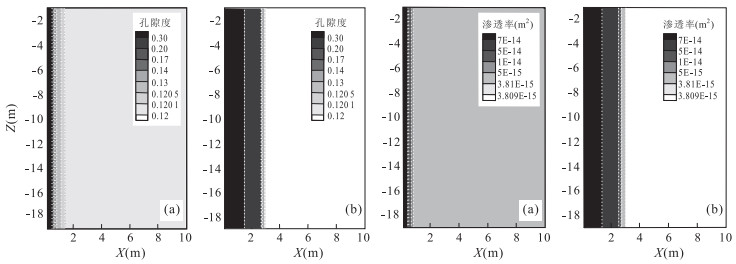

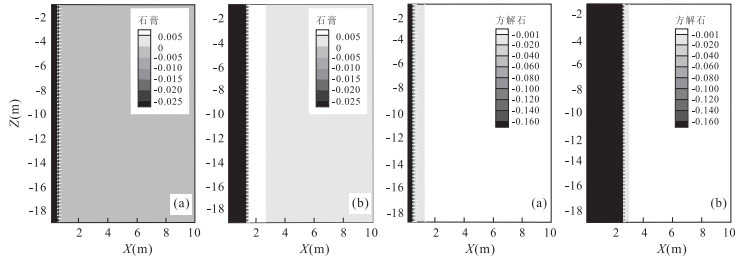

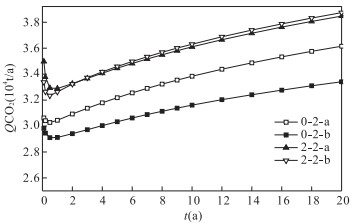

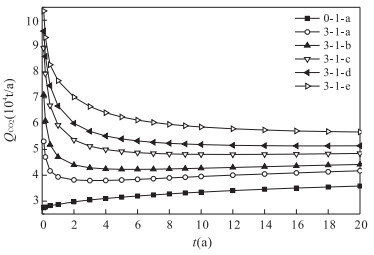

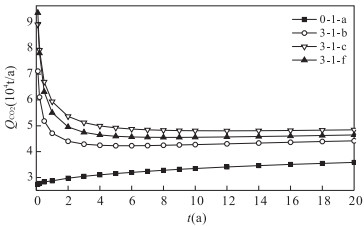

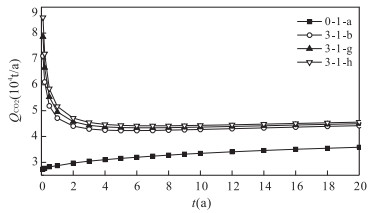

摘要: 注入性是关系CO2地质储存成功与否的一个关键的技术和经济问题, 评价与提高CO2在中国陆相沉积盆地普遍存在的低渗储层中的注入能力对于碳捕集与封存技术在中国的应用与推广具有重要意义.以江汉盆地江陵凹陷为例, 通过数值模拟的方法开展高盐低渗储层CO2注入能力评估与提高方案研究.结果表明: 预注入淡水和低盐度的微咸水溶液均可不同程度地缓解注入井周围的盐沉淀问题; 预注入CO2饱和溶液或稀盐酸溶液, 可显著提高注入井周围的孔渗值, 提高CO2注入性, 但由于储层本身的低渗性, 迁移距离有限, 短时间内较难实现CO2注入速率的大幅度提高.采取水力压裂措施可显著提高低渗储层中CO2的注入性, 其提升能力取决于压裂裂缝的半长度以及压裂程度.对于单个垂直井, 通过水力压裂对储层加以改造, 并采取多层注入的方式, 在低渗储层中实现数十万吨的年注入量是可能的.Abstract: Injectivity is a crucial technical and economical issue for CO2 geological storage projects due to large volumes of CO2 to be stored. Assessment and enhancement of CO2 injectivity in ubiquitous low-permeability reservoirs in the continental sedimentary basins of China is of great significance to the application and development of carbon capture and storage (CCS) in China. Numerical simulation was carried out to investigate the potential and enhancement of CO2 injectivity in high-salinity and low-permeability aquifers by taking Jiangling depression of Jianghan basin as the study area. The results show that pre-injection of freshwater and low-salinity saline water can effectively mitigate salt precipitation around the CO2 injection well at different levels; pre-injection of CO2-saturation solution and diluted HCl solution can significantly improve the porosity and permeability values and enhance CO2 injectivity. However, it is difficult to achieve a significant increase in CO2 injection rate in a short time due to the limited migration distance resulted from the low-permeability nature. Hydraulic fracturing measures can significantly increase CO2 injectivity and the improved capacity largely depends on fracturing half-length and fracturing degree. Therefore, for a single vertical well, it is possible to achieve the injection of hundreds of thousands of tons of CO2 per year to low-permeability reservoirs by adopting hydraulic fracturing measures and multi-layer injection.

-

Key words:

- CO2 injectivity /

- high salinity /

- low-permeability aquifer /

- enhancement measure /

- hydrogeology

-

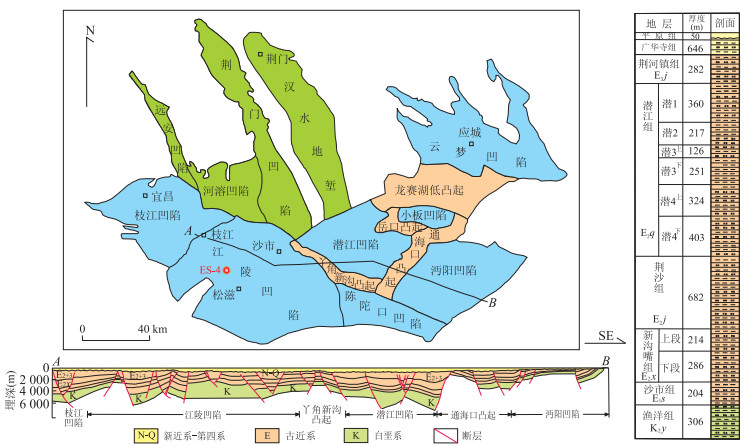

图 1 江汉盆地地理位置、构造单元及柱状图(李国玉和吕鸣岗,2002)

Fig. 1. Location, geological units and stratum histogram of Jianghan basin

表 1 直接注入、预注入淡水或微咸水、CO2饱和溶液或稀盐酸以及水力压裂具体实施方案

Table 1. Schemes of direct injection, pre-injection of freshwater or brackish water, pre-injection of CO2-saturated solution or diluted HCl solution and hydraulic fracturing

方案代号 方案内容 基础方案:直接注入CO2模型的影响 0-1-a、0-1-b 3D模型不考虑盐沉淀的影响(0-1-a)、考虑盐沉淀的影响(0-1-b) 0-2-a、0-2-b 2D模型不考虑盐沉淀的影响(0-2-a)、考虑盐沉淀的影响(0-2-b) 提升方案1:预注入淡水、微咸水溶液(3D模型) 1-1-a、1-1-b、1-1-c 预注入10d淡水、1%盐度微咸水、5%盐度弱咸水后直接注入CO2 1-2-a、1-2-b、1-2-c 预注入10d淡水、1%盐度微咸水、5%盐度弱咸水后等待压力恢复20d后再注入CO2 提升方案2:预注入CO2饱和溶液、稀盐酸溶液(2D模型) 2-1-a、2-1-b 预注入30d CO2饱和溶液、1mol/L稀盐酸溶液后直接注入CO2 2-2-a、2-2-b 预注入30d CO2饱和溶液、1mol/L稀盐酸溶液后等待压力恢复30d后再注入CO2 提升方案3:水力压裂(3D模型) 3-1-a至3-1-e 压裂长度的影响:X方向压出一条半长度50m、100m、200m、300m、500m的垂直裂缝 3-1-f 压裂数目的影响:X方向和Y方向各压裂出一条半长度为100m的垂直裂缝 3-1-g、3-1-h 压裂程度的影响:以半长度100m裂缝为例,将裂缝渗透率提高至2倍和5倍,考察压裂程度的影响 表 2 基础方案中水文地质参数和热力学参数设置

Table 2. Hydrogeological and thermo dynamical properties used in the base-case simulations

岩性 孔隙度(%) 渗透率(10-15 m2) 岩石颗粒密度(g/cm3) 岩石热传导率(W/m℃) 岩石颗粒特焓(J/kg℃) 压缩系数(Pa-1) 盐度(%) 残余水饱和度Slr 残余气饱和度Sgr Van Genuchten参数λ 压强系数(MPa) 砂岩 12 3.81 2.6 2.51 920 4.5E-10 20 0.30 0.05 0.46 0.02 表 3 模型中原生矿物体积分数以及可能的次生矿物

Table 3. Initial mineral volume fractions and possible secondary mineral phases used in the simulations

原生矿物 化学组成 体积分数 次生矿物 化学组成 体积分数 石英 SiO2 0.70 高岭石 Al2Si2O5(OH) 0 方解石 CaCO3 0.20 钙蒙脱石 Ca0.145Mg0.26Al1.77Si3.97O10(OH)2 0 钠长石 NaAlSi3O8 0.01 钠蒙脱石 Na0.290Mg0.26Al1.77Si3.97O10(OH)2 0 石膏 CaSO4 0.03 铁白云石 CaMg0.3Fe0.7(CO3)2 0 伊利石 K0.6Mg0.25Al1.8(Al0.5Si3.5O10)(OH)2 0.03 片钠铝石 NaAlCO3(OH)2 0 绿泥石 Mg2.5Fe2.5Al2Si3O10(OH)8 0.01 白云石 CaMg(CO3)2 0 赤铁矿 Fe2O3 0.01 菱镁矿 MgCO3 0 钾长石 KAlSi3O8 0.01 菱铁矿 FeCO3 0 黄铁矿 FeS2 0 表 4 地层水初始溶解组分浓度

Table 4. Initial concentrations of the formation water at reservoir conditions of 90℃ and 2.25×107 Pa

成分 浓度(mol/kg H2O) 成分 浓度(mol/kg H2O) 成分 浓度(mol/kg H2O) pH 6.9 K 3.439×10-2 S 6.273×10-2 Ca 6.350×10-2 Fe 1.477×10-6 Al 1.768×10-8 Mg 4.567×10-4 SiO2(aq) 1.016×10-3 Cl 4.000 Na 4.002 C 7.013×10-3 O2(aq) 1.447×10-5 -

Alkan, H., Cinar, Y., lker, E.B., 2010. Impact of Capillary Pressure, Salinity and In-Situ Conditions on CO2 Injection into Saline Aquifers. Transport in Porous Media, 84(3): 799-819. doi: 10.1007/s1124-010-9541-8 Bacci, G., Korre, A., Durucan, S., 2011. An Experimental and Numerical Investigation into the Impact of Dissolution/Precipitation Mechanisms on CO2 Injectivity in the Wellbore and Far Field Regions. International Journal of Greenhouse Gas Control, 5(3): 579-588. doi: 10.1016/j.ijggc.2011.05.007 Benson, S.M., Cole, D.R., 2008. CO2 Sequestration in Deep Sedimentary Formations. Elements, 4(5): 325-331. doi: 10.2113/gselements.4.5.325 Gale, J., 2004. Geological Storage of CO2: What Do We Know, Where Are the Gaps, and What More Needs to Be Done. Energy, 29(9-10): 1329-1338. doi: 10.1016/j.energy.2004.03.068 Giorgis, T., Carpita, M., Battistelli, A., 2007.2D Modeling of Salt Precipitation during the Injection of Dry CO2 in a Depleted Gas Reservoir. Energy Conversion and Management, 48(6): 1816-1826. doi: 10.1016/j.enconman.2007.01.012 Holloway, S., 2005. Underground Sequestration of Carbon Dioxide—A Viable Greenhouse Gas Mitigation Option. Energy, 30: 2318-2333. doi: 10.1016/j.energy.2003.10.023 IPCC (Intergovernmental Panel on Climate Change), 2005. Special Report on Carbon Dioxide Capture and Storage. Cambridge University Press, New York. Kim, K.Y., Han, W.S., Oh, J., et al., 2012. Characteristics of Salt-Precipitation and the Associated Pressure Buildup during CO2 Storage in Saline Aquifers. Transport in Porous Media, 92: 397-418. doi: 10.1017/s11242-011-9909-4 Li, G.Y., Lü, M.G., 2002. Atlas of China's Petroliferous Basins. Petroleum Industry Press, Beijing (in Chinese). Li, Y.L., Fang, Q., Ke, Y.B., et al., 2012. Effect of High Salinity on CO2 Geological Storage: A Case Study of Qianjiang Depression in Jianghan Basin. Earth Science—Journal of China University of Geosciences, 37(2): 283-288 (in Chinese with English abstract). doi: 10.3799/dqkx.2012.030 Palandri, J.L., Kharaka, Y.K., 2004. A Compilation of Rate Parameters of Water-Mineral Interaction Kinetics for Application to Geochemical Modeling. Menlo Park, California, 1068: 64. Pruess, K., Müller, N., 2009. Formation Dry-Out from CO2 Injection into Saline Aquifers: 1. Effects of Solids Precipitation and Their Mitigation, Water Resources Research, 45(3): W03402. doi: 10.1029/2008WR007101 Pruess, K., Oldenburg, C., Moridis, G., 1999. TOUGH2 User's Guide. Earth Sciences Division, Lawrence Berkeley National Laboratory, University of California, Berkeley. Verma, A., Pruess, K., 1988. Thermohydrological Conditions and Silica Redistribution near High-Level Nuclear Wastes Emplaced in Saturated Geological Formations. Journal of Geophysical Research, 93(B2): 1159-1173. doi: 10.1029/JB093iB02p01159 Wang, Y.X., Mao, X.M., DePaolo, D., 2011. Nanoscale Fluid-Rock Interaction in CO2 Geological Storage. Earth Science—Journal of China University of Geosciences, 36(1): 163-171 (in Chinese with English abstract). doi: 10.3799/dqkx.2011.017 Xu, T., Sonnenthal, E., Spycher, N., et al., 2008. TOUGHREACT User's Guide: A Simulation Program for Non-Isothermal Multiphase Reactive Geochemical Transport in Variably Saturated Geologic Media, V1.2.1. Earth Sciences Division, Lawrence Berkeley National Laboratory, University of California, Berkeley. Zhang, K., Wu, Y.S., Pruess, K., 2008. User's Guide for TOUGH2-MP—A Massively Parallel Version of the TOUGH2 Code. Earth Sciences Division, Lawrence Berkeley National Laboratory, University of California, Berkeley. Zhang, W., Li, Y., Omambia, A., 2010. Reactive Transport Modeling of Effects of Convective Mixing on Long-Term CO2 Geological Storage in Deep Saline Formations. International Journal of Greenhouse Gas Control, 5(2): 241-256. doi: 10.1016/j.ijggc.2010.10.007 Zhang, W., Li, Y., Xu, T., et al., 2009. Long-Term Variations of CO2 Trapped in Different Mechanisms in Deep Saline Formations: A Case Study of the Songliao Basin, China. International Journal of Greenhouse Gas Control, 3(2): 161-180. doi: 10.1016/j.ijggc.2008.07.007 李国玉, 吕鸣岗, 2002. 中国含油气盆地图集. 北京: 石油工业出版社. 李义连, 房琦, 柯怡兵, 等, 2012. 高盐度卤水对CO2地质封存的影响: 以江汉盆地潜江凹陷为例. 地球科学——中国地质大学学报, 37(2): 283-288. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX201202013.htm 王焰新, 毛绪美, DePaolo, D., 2011. CO2地质储存的纳米尺度流体-岩石相互作用研究. 地球科学——中国地质大学学报, 36(1): 163-171. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX201101018.htm -

下载:

下载: