The Micro-Flow Mathematical Model Study on Viscoelastic Polymer Displacement Viscous Oil

-

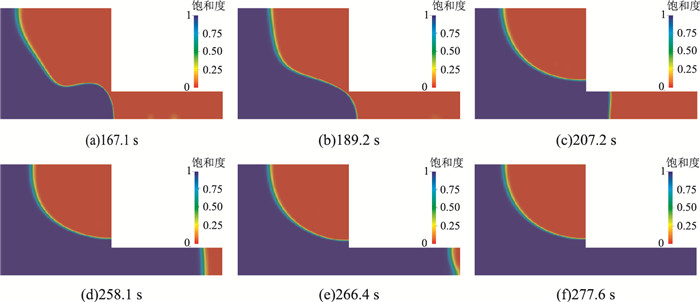

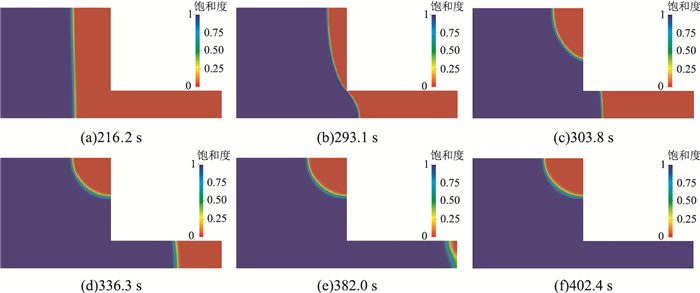

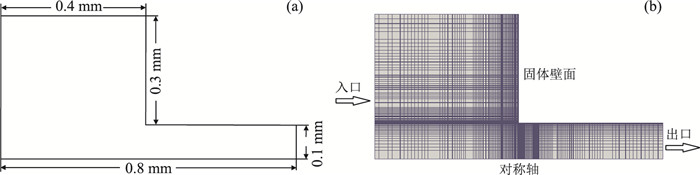

摘要: 我国海上稠油资源比较丰富,但由于受到海上条件等因素限制,聚合物驱成为提高海上稠油采收率的主要方法.因此深化聚合物溶液驱稠油微观渗流机理对于进一步提高采收率具有十分重要的意义.目前关于粘弹性聚合物渗流机理的理论研究主要局限于弹性聚合物溶液的单相流体在微观孔道内流动特征研究,而针对粘弹性聚合物、油两相流体渗流机理的研究甚少,特别是针对稠油聚合物驱的相关研究未见报道.为此,借助于计算方法较为成熟的OpenFOAM开源平台开展了聚合物驱稠油两相流体渗流机理的研究;以收缩孔道为微观物理模型,建立了粘弹性聚合物溶液、普通稠油两相渗流连续性方程、运动方程及本构方程,并采用VOF(volume of fluid)界面追踪方法建立两相界面相方程;以OpenFOAM开源平台为基础,开发了粘弹性流体、幂律流体两相流体求解器;绘制了不同弹性聚合物溶液在微观孔道内驱油的饱和度分布、速度分布及应力分布特征.结果表明,相对于水驱,纯粘性聚合物溶液前缘突破时间慢,波及面积大,驱油效率高.相比于同等粘度的纯粘性聚合物溶液,粘弹性聚合物的弹性有助于挖潜凸角内的残余油,聚合物溶液的弹性越大,稠油驱油效率越高.随着聚合物溶液弹性的增强,第一法向应力增大,当聚合物溶液进入到孔道突变处时,其弹性发挥的作用最大,法向应力的值最大.研究结果可为矿场实施聚合物驱设计、筛选聚合物溶液提供重要的理论支持.Abstract: With the development of economy and the rising demand for oil resources, the exploitation of viscous oil, bitumen and oil shale is an important challenge for the oil industry while the recoverable reserves of conventional crude is decreasing constantly. The viscous oil resources of our country is rich, but the polymer flooding is the main method enhancing viscous oil recovery due to restrictions of non-available steam generation facilities off-shore. So it is significant to study on micro flow mechanism deeply for further enhancing viscous oil recovery. The existing study on the polymer flow mechanism is mainly limited to the single phase flow in micro pore, and little study of viscoelastic polymer and oil two-phase flow characteristic has been done especially with viscous oil. In this study, we develop two phases of viscoelastic polymer and viscous oil solver on the OpenFOAM platform based on computational fluid dynamics, and we study the mechanism of viscoelastic polymer flooding viscous oil based on the solver. In this paper, the contraction model and mathematical model is established, including the continuity equation, momentum equation and constitutive equation of two phases, and interface equation solved by VOF (volume of fluid) method. The solver of viscoelastic and power law fluid is developed based on OpenFOAM. The saturation, velocity and stress distribution is drawn with different elastic polymer solutions. The results show that the front breakthrough time is slower, the sweep efficiency is larger and displacement efficiency is higher than water flooding. The elasticity of polymer can enhance oil recovery. The larger is the elasticity, the smaller the dead oil area in convex corner. The stronger of elasticity is, the lager of normal stress is. The elasticity can make the most of displacement oil when the polymer flows in contraction of the model. The results of this paper can supply the theoretical support basis on polymer design and filter, it is significant for implementation of polymer flooding in oil field.

-

Key words:

- viscoelastic polymer /

- normal stress /

- two phase flow /

- OpenFOAM /

- displacement efficiency /

- petroleum geology

-

表 1 收缩孔道两相渗流模拟参数

Table 1. Simulation parameters of two-phase seepage flow for contraction model

模拟方案 油相 驱替相 界面张力(mN/m) 入口速度(10-4 m/s) 密度(kg/m3) 粘度(mPa·s) 密度(kg/m3) 粘度(mPa·s) 松弛时间(s) 水驱普通稠油 860 70 1 000 1 - 4.8 1.16 纯粘性聚合物驱普通稠油 962 70 900 40 0.00 4.8 1.16 粘弹性聚合物驱普通稠油 962 70 900 40 0.09 4.8 1.16 表 2 收缩孔道不同驱替方式的驱替效率

Table 2. Displacement efficiency of different flooding patterns in contraction model

水驱 纯粘性聚合物驱 粘弹性聚合物驱(λ=0.09s) 驱替时刻(s) 驱替效率(%) 驱替时刻(s) 驱替效率(%) 驱替时刻(s) 驱替效率(%) 161.7 40.20 216.2 52.74 216.2 52.89 189.2 47.56 293.1 73.54 293.1 73.60 207.2 52.82 303.8 75.55 303.8 76.18 258.1 64.39 336.3 82.38 336.3 82.81 266.4 66.44 382.0 88.61 382.0 89.76 277.6 68.26 402.4 91.09 402.4 92.09 表 3 第一法向应力(τxx)变化对比

Table 3. Comparison of first normal-stress (τxx)

驱替时刻(s) 216.2 293.1 303.8 336.3 382 402.4 最大第一法向应力

Maxtauxx(Pa)纯粘性聚合物驱 0.060 4 0.381 5 1.152 3 0.295 4 1.182 6 0.035 4 粘弹性聚合物驱 0.061 3 1.472 2 4.560 1 5.001 2 1.485 3 0.058 1 最大第一法向应力差(Pa) 0.000 9 1.090 7 3.407 8 4.705 8 0.302 7 0.022 7 -

Alkafeef, S.F., Zaid, A.M., 2007.Review of and Outlook for Enhanced Oil Recovery Techniques in Kuwait Oil Reservoirs.International Petroleum Technology Conference, Dubai.doi:10.2523/11234-ms Beliveau, D., 2009.Waterflooding Viscous Oil Reservoirs.SPE Reservoir Evaluation & Engineering, 12(5):689-701.doi: 10.2118/113132-pa Cai, J.C., Yu, B.M., 2012.Advances in Studies of Spontaneous Imbibition in Porous Media.Advances in Mechanics, 42(6):735-754 (in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTOTAL-LXJZ201206006.htm Doorwar, S., Mohanty, K.K., 2011.Viscous Fingering during Non-Thermal Heavy Oil Recovery.SPE Annual Technical Conference and Exhibition, Denver.doi:10.2118/146841-ms Favero, J.L., Secchi, A.R., Cardozo, N.S.M., et al., 2010.Viscoelastic Flow Analysis Using the Software OpenFOAM and Differential Constitutive Equations.Journal of Non-Newtonian Fluid Mechanics, 165(23-24):1625-1636.doi: 10.1016/j.jnnfm.2010.08.010 Gao, P.Q., Towler, B., 2011.Investigation of Polymer and Surfactant-Polymer Injections in South Slattery Minnelusa Reservoir, Wyoming.Journal of Petroleum Exploration and Production Technology, 1(1):23-31.doi: 10.1007/s13202-010-0002-2 Jones, W.M., 1980.Polymer Additives in Reservoir Flooding for Oil Recovery:Shear Thinning or Shear Thickening?Journal of Physics D:Applied Physics, 13(5):L87-L88.doi: 10.1088/0022-3727/13/5/004 Lake, L., Schmidt, R., Venuto, P., 1992.A Niche for Enhanced Oil Recovery in the 1900s.Oilfield Review, 4(1):55-61. Liu, X.L., Duan, M.L., Gao, P., et al., 2015.Development of Numerical Wave Flumes Based on OpenFOAM.Journal of Fudan University (Natural Science), 54(3):373-378 (in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTotal-FDXB201503016.htm Maerker, J.M., 1975.Shear Degradation of Partially Hydrolyzed Polyacrylamide Solutions.SPE Journal, 15(4):311-322.doi: 10.2118/5101-pa Maerker, J.M., Sinton, S.W., 1986.Rheology Resulting from Shear-Induced Structure in Associating Polymer Solutions.Journal of Rheology, 30(1):77-99.doi: 10.1122/1.549898 Meyer, R.F., Attanasi, E.D., 2003.Heavy Oil and Natural Bitumen-Strategic Petroleum Resources.Proceedings of the National Academy of Sciences of the United States of America, 94(23):12331-6. https://pubs.er.usgs.gov/publication/fs07003 Schroeder, C.M., Babcock, H.P., Shaqfeh, E.S., et al., 2003.Observation of Polymer Conformation Hysteresis in Extensional Flow.Science, 301(5639):1515-1519.doi: 10.1126/science.1086070 Seright, R.S., Fan, T.G., Wavrik, K.E., et al., 2011.New Insights into Polymer Rheology in Porous Media.SPE Journal, 16(1):35-42.doi: 10.2118/129200-pa Sheng, J.J., Leonhardt, B., Azri, N., 2015.Status of Polymer-Flooding Technology.Journal of Canadian Petroleum Technology, 54(2):116-126.doi: 10.2118/174541-pa Su, Y.H., 2009.Study on Economic and Technical Limits of Heavy Oil Steam Huff and Puff in Shengli Oilfield (Dissertation).China University of Petroleum, Dongying (in Chinese with English abstract). Wang, D.M., Cheng, J.C., Xia, H.F., et al., 2002.Improvement of Displacement Efficiency of Cores by Driving Forces Parallel to the Oil-Water Interface of Viscous-Elastic Fluid.Acta Petrolei Sinica, 23(5):47-52 (in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTOTAL-SYXB200205010.htm Wang, D.M., Cheng, J.C., Yang, Q.Y., 2000.Viscous-Elastic Polymer Can Increase Micro-Scale Displacement Efficiency in Cores.Acta Petrolei Sinica, 21(5):45-51 (in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTOTAL-SYXB200005013.htm Xia, H.F., Wang, D.M., Liu, Z.C., et al., 2001.Study on the Mechanism of Polymer Solution with Visco-Elastic Behavior Increasing Microscopic Oil Displacement Efficiency.Acta Petrolei Sinica, 22(4):60-65 (in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTOTAL-SYXB200104016.htm Xie, Y., 2014.The Microcosmic Mechanism of Viscoelastic Polymer Flooding Heavy Oil (Dissertation).Northeastern Petroleum University, Daqing (in Chinese with English abstract). Xu, Q.Q., 2013.Research on Adaptable from Flooding and Profile Control in Bohai SZ36-1 (Dissertation).China University of Petroleum, Dongying (in Chinese with English abstract). Yang, Y.F., Wang, C.C., Yao, J., et al., 2016.A New Method for Microscopic Pore Structure Analysis in Shale Matrix.Earth Science, 41(6):1067-1073 (in Chinese with English abstract). http://linkinghub.elsevier.com/retrieve/pii/S0016236116303118 Yin, H.J., Jiang, H.M., Su, Y.C., et al., 2009.Flow Behavior of Viscoelastic Polymer Solution in the Expansion Channel.Acta Polymerica Sinica, 1(6):520-524 (in Chinese with English abstract). http://www.oalib.com/paper/1580937 Yin, H.J., Wang, D.M., Zhong, H.Y., et al., 2012.Flow Characteristics of Viscoelastic Polymer Solution in Micro-Pores.SPE EOR Conference at Oil and Gas West Asia, Muscat.doi:10.2118/154640-ms Yue, X.A., Zhang, L.J., Liu, Z.C., et al., 2002.Viscoelastic Flow and Microscopic Displacement Mechanism of Polymer Solution in Reservoir Pores.Oil & Gas Recovery Technology, 9(3):4-6 (in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTOTAL-YQCS200203001.htm Zheng, Y.F., Chen, R.X., Xu, Z., et al., 2016.The Transport of Water in Subduction Zones.Science China:Earth Sciences, 59(4):651-681.doi: 10.1007/s11430-015-5258-4 Zhong, H.Y., Tian, Z., Yin, H.J., 2012.Flow of Viscoelastic Polymer Solutions through a Planar Contraction with a Boundary Layer Effect.Chemistry and Technology of Fuels and Oils, 48(5):393-402.doi: 10.1007/s10553-012-0386-4 Zhou, S.W., 2009.Exploration and Practice of Offshore Oilfield Effective Development Technology.Engineering Science, 11(10):55-60 (in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTOTAL-GCKX200910009.htm Zhou, W., Zhang, J., Feng, G.Z., et al., 2008.Key Technologies of Polymer Flooding in Offshore Oilfield of Bohai Bay.SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth.doi:10.2118/115240-ms 蔡建超, 郁伯铭, 2012.多孔介质自发渗吸研究进展.力学进展, 42(6): 735-754. doi: 10.6052/1000-0992-11-096 刘秀丽, 段梦兰, 高攀, 等, 2015.基于OpenFOAM的数值波浪水槽研究.复旦学报(自然科学版), 54(3): 373-378. http://cdmd.cnki.com.cn/Article/CDMD-10536-1013300484.htm 苏映宏, 2009. 胜利油田稠油蒸汽吞吐开发经济技术界限研究(硕士学位论文). 东营: 中国石油大学. http://d.wanfangdata.com.cn/Thesis/Y1542804 王德民, 程杰成, 夏惠芬, 等, 2002.粘弹性流体平行于界面的力可以提高驱油效率.石油学报, 23(5): 47-52. http://www.cnki.com.cn/Article/CJFDTOTAL-SYXB200205010.htm 王德民, 程杰成, 杨清彦, 2000.粘弹性聚合物溶液能够提高岩心的微观驱油效率.石油学报, 21(5): 45-51. doi: 10.7623/syxb200005010 夏惠芬, 王德民, 刘中春, 等, 2001.粘弹性聚合物溶液提高微观驱油效率的机理研究.石油学报, 22(4): 60-65. doi: 10.7623/syxb200104012 谢毅, 2014. 黏弹性聚合物驱稠油微观机理研究(硕士学位论文). 大庆: 东北石油大学. http://cdmd.cnki.com.cn/Article/CDMD-10220-1014384351.htm 许青青, 2013. 渤海SZ36-1油田泡沫调驱适应性研究(硕士学位论文). 东营: 中国石油大学. http://cdmd.cnki.com.cn/Article/CDMD-10425-1015025749.htm 杨永飞, 王晨晨, 姚军, 等, 2016.页岩基质微观孔隙结构分析新方法.地球科学, 41(6): 1067-1073. doi: 10.11764/j.issn.1672-1926.2016.06.1067 尹洪军, 姜海梅, 苏宇驰, 等, 2009.黏弹性聚合物溶液在突扩孔道内的流动特性.高分子学报, 1(6): 520-524. http://www.cnki.com.cn/Article/CJFDTOTAL-GFXB200906005.htm 岳湘安, 张立娟, 刘中春, 等, 2002.聚合物溶液在油藏孔隙中的流动及微观驱油机理.油气地质与采收率, 9(3): 4-6. http://cdmd.cnki.com.cn/Article/CDMD-10220-2004050654.htm 周守为, 2009.海上油田高效开发技术探索与实践.中国工程科学, 11(10): 55-60. doi: 10.3969/j.issn.1009-1742.2009.10.008 -

下载:

下载: