Micropore Structure Evolution of Organic Matters in Coal Measures due to Bioconversion Using FE-SEM, HIP and N2 Adsorption Experiments

-

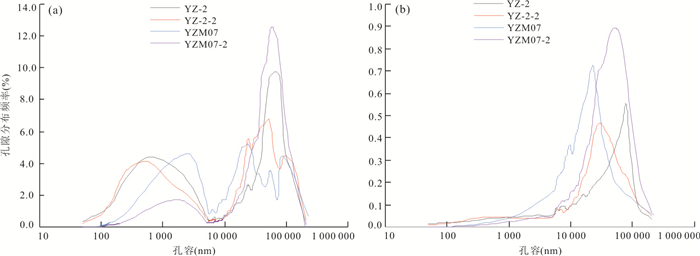

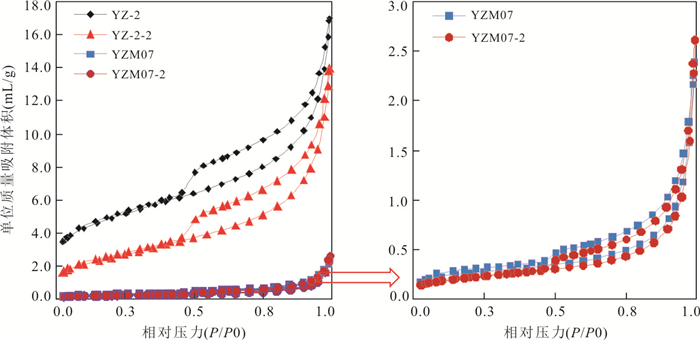

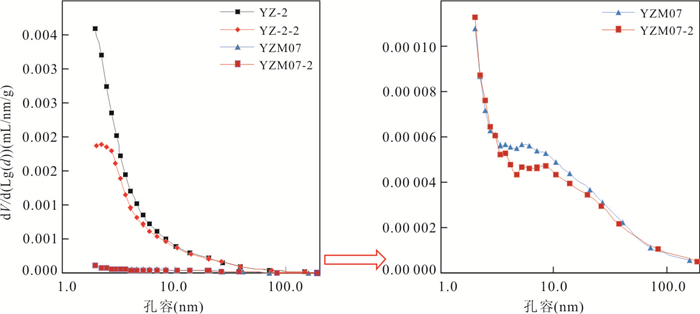

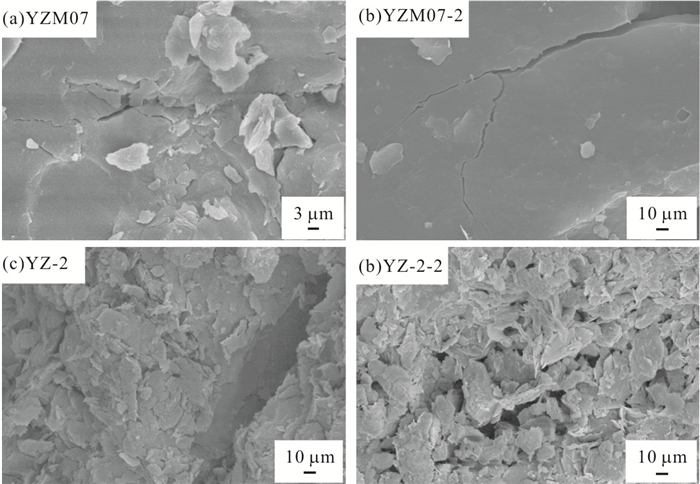

摘要: 微生物降解前后的煤系有机岩(煤岩和泥页岩)储层微观孔隙结构的变化对生物成气和成藏过程具有重要的意义.利用场发射扫描电子显微镜、高压压汞仪、孔比表面积孔隙度分析仪以及分形维数理论对厌氧微生物降解前后的煤系有机岩样品储层孔隙结构演化进行分析,根据孔隙结构特征并结合微生物生态学特征,将生物气化煤系有机岩的孔隙结构类型分为3类,即孔隙直径大于5 μm的微米孔,孔隙直径介于5 μm~100 nm的微纳孔,以及孔隙直径小于100 nm大于2 nm的纳米孔.微生物作用后的煤岩与泥页岩的微米孔孔容增加,微纳孔和纳米孔孔容减小,孔隙比表面积降低,平均孔隙直径增大.分形维数对比结果表明受微生物作用的煤岩与泥页岩样品的面分形维数(D1)和孔隙结构分形维数(D2)均降低,微生物作用使得有机岩孔隙表面变的光滑,孔隙结构变得简单,有利于游离气的运移和富集.Abstract: Micropore structure characterization of organic matters in the coal measures due to bioconversion is of great significance in understanding reservoir reformation by microorganism and revealing the storage and enrichment mechanism of biogenic gas in the coal measures. Pore structure evolution of organic matters in the coal measures degraded by microbe was analyzed using field emission scanning electron microscopy (FE-SEM), high-pressure mercury intrusion porosimetry (MIP), low-pressure N2 gas adsorption pycnometry and fractal dimension FHH theory in this study. Considering the measuring range of pore size distribution (PSD) and combining the characteristics of microbial ecology, the pore structure type of coal and shale in coal measures is divided into three types. They are micropore (PSD>5 μm), micro-nanopore (5 μm-100 nm), and nanopore (2-100 nm). The PSD and micropore pore volume (PV) of coal and shale samples increase, and the specific surface area (SSA) and micro-nanopore and nanopore PV decrease after bioconversion. The surface fractal diameter (D1) and pore structure fractal diameter (D2) of coal and shale samples decrease after bioconversion, showing that the inner surface of pore becomes smooth and pore structure gets simple due to microbial action. The reformation of pore structure due to bioconversion is benefitial to the migration and enrichment of free gas in the coal measures.

-

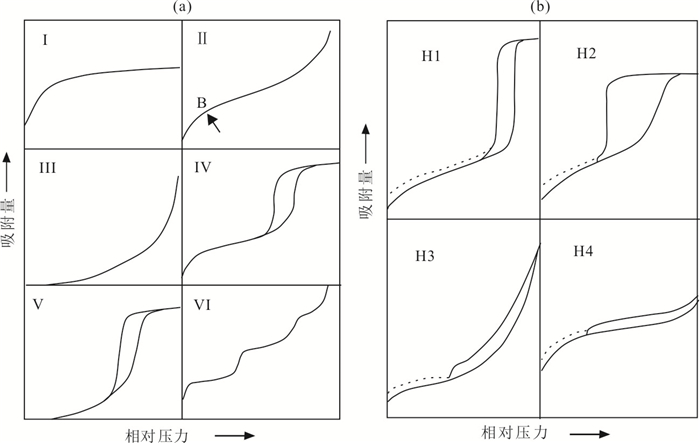

图 3 根据IUPAC分类的吸附等温线类型(a)与滞留环类型(b)

Fig. 3. Sorption isotherm types (a) and hysteresis loops (b) according to IUPAC classifications

表 1 关于煤岩和泥页岩样品的基本参数和生物气化的甲烷产气率数据

Table 1. Data of coal and mudstone basic parameters and biogenic methane yields

样品编号 岩石类型 成熟度(Ro, max, %) 有机质含量(TOC, %) 甲烷产率(µmol/g) YZ-2 泥页岩 1.58 15.0 21 YZ-2-2a / 13.2 - YZM07 煤 2.50 / 150 YZM07-2a / / - 注:a为微生物降解后的样品;/为实验未测;-为无数据.在3~4个月后,甲烷生烃量达到高峰,然后甲烷生烃量迅速下降,甲烷菌开始死亡( Bao et al., 2016 ).本次试验选取123天.表 2 基于高压压汞和低压氮气吸附数据的孔隙分类的孔容、比表面积和孔径分布

Table 2. Pore volume (PV), specific surface area (SSA) and pore size distribution (PSD) based on pore structure classification by MIP, N2 physisorption for coal and shale samples

样品编号 岩石类型 基于MIP数据的微米孔与微纳孔 基于N2吸附的纳米孔 PV (cm3/100 g) SSA (m2/g) PSDa (µm) BJH PV (cm3/100 g) BET SSA (m2/g) DFT PV (cm3/100 g) PSDb (nm) > 5 µm 100 nm~5 µm > 100 nm 2~100 nm YZ-2 泥页岩 30.51 8.74 4.62 0.34 2.63 17.43 0.28 6.87 YZ-2-2 34.49 7.47 2.45 0.68 2.16 9.12 0.07 7.84 YZM07 煤 48.67 8.37 1.23 1.85 0.37 0.96 0.01 14.78 YZM07-2 67.40 3.79 0.74 3.85 0.36 0.80 0.006 16.20 注:aPSD为通过压汞法测得的平均孔径,bPSD为根据BJH解吸分支等温线计算得到平均孔径. 表 3 煤岩与泥页岩高压压汞进汞率和孔容分布数据

Table 3. Data of pore frequency and pore volume based on MIP for coal and shale samples

YZ-2 YZ-2-2 YZM07 YZM07-2 孔隙直径

(nm)进汞率

(%)dV/d

(lgd)孔隙直径

(nm)进汞率

(%)dV/d

(lgd)孔隙直径

(nm)进汞率

(%)dV/d

(lgd)孔隙直径

(nm)进汞率

(%)dV/d

(lgd)206 900 0.14 0.04 206 900 0.40 0.05 223 100 0.72 0.05 204 400 0.00 0.06 126 900 3.08 0.09 126 900 4.05 0.11 130 800 3.24 0.10 133 100 3.47 0.21 92 570 5.22 0.35 92 570 4.45 0.19 83 490 4.46 0.14 95 470 6.72 0.50 78 980 9.34 0.55 78 980 3.65 0.23 71 450 1.71 0.16 72 280 11.63 0.79 66 510 9.74 0.45 66 510 4.17 0.25 54 690 3.57 0.19 57 080 12.56 0.89 53 050 9.30 0.36 53 050 6.78 0.32 46 760 2.55 0.24 47 100 10.37 0.89 44 520 6.82 0.30 44 520 6.45 0.39 41 030 2.70 0.31 39 370 9.40 0.81 38 350 4.31 0.26 38 350 6.29 0.42 36 120 3.34 0.36 34 870 5.66 0.74 33 790 3.44 0.23 33 790 5.70 0.45 32 050 3.35 0.42 30 920 5.27 0.72 30 080 2.90 0.22 30 080 5.62 0.47 28 410 4.63 0.56 27 660 4.90 0.69 27 180 2.32 0.20 27 180 4.82 0.45 25 440 5.09 0.65 24 870 4.09 0.57 24 060 2.66 0.19 24 060 5.56 0.41 23 050 5.20 0.73 22 360 3.35 0.46 21 510 2.20 0.17 21 510 4.39 0.35 21 030 5.07 0.70 20 250 2.42 0.38 19 540 1.72 0.15 19 540 3.10 0.28 19 020 4.99 0.63 18 430 2.11 0.36 17 670 1.50 0.14 17 670 2.51 0.24 17 230 4.48 0.57 16 830 1.92 0.33 16 040 1.52 0.15 16 040 2.36 0.22 15 730 3.74 0.54 15 440 1.54 0.27 14 650 1.39 0.13 14 650 1.89 0.19 14 460 3.38 0.50 14 180 1.32 0.24 13 530 1.08 0.12 13 530 1.36 0.15 13 270 2.97 0.44 13 140 0.92 0.19 12 510 0.97 0.11 12 510 1.09 0.13 12 220 2.70 0.42 12 140 0.87 0.18 11 590 0.88 0.10 11 590 1.04 0.13 11 300 2.29 0.36 11 310 0.74 0.16 10 830 0.78 0.10 10 830 0.86 0.11 10 540 1.75 0.33 10 550 0.70 0.16 10 180 0.70 0.10 10 180 0.65 0.10 9 852 1.72 0.37 9 786 0.77 0.15 9 624 0.56 0.09 9 624 0.56 0.10 9 267 1.76 0.36 9 176 0.47 0.12 9 122 0.52 0.08 9 122 0.48 0.08 8 715 1.52 0.32 8 680 0.44 0.13 8 541 0.57 0.08 8 541 0.55 0.08 8 192 1.51 0.31 8 220 0.4 0.12 8 061 0.55 0.09 8 061 0.42 0.07 7 753 1.20 0.26 7 788 0.39 0.12 7 670 0.53 0.10 7 670 0.37 0.07 7 366 0.92 0.25 7 418 0.33 0.12 7 299 0.52 0.09 7 299 0.34 0.08 7027 0.88 0.25 7 036 0.40 0.11 6 874 0.63 0.09 6 874 0.52 0.08 6 626 1.06 0.23 6 690 0.32 0.10 6 463 0.56 0.08 6 463 0.47 0.08 6 238 1.08 0.23 6 327 0.32 0.09 6 128 0.45 0.08 6 128 0.45 0.08 5 909 0.88 0.21 5 999 0.29 0.09 5 839 0.42 0.07 5 839 0.45 0.08 5 568 0.87 0.17 5 691 0.28 0.08 5 507 0.42 0.06 5 507 0.39 0.05 4 434 2.47 0.14 5 146 0.31 0.05 4 443 1.15 0.05 4 443 0.88 0.04 2 748 4.58 0.10 3 600 1.03 0.05 2 868 2.61 0.05 2 868 1.81 0.04 1 248 3.99 0.05 1 881 1.72 0.04 1 420 3.87 0.05 1 420 2.70 0.04 49 2.21 0.02 770 1.37 0.02 568.8 4.39 0.04 569 4.11 0.05 236 0.77 0.01 349 0.64 0.01 259.4 3.07 0.03 259 3.56 0.04 142 0.26 0.01 201 0.24 0.01 149.3 1.49 0.02 149 1.69 0.02 96 0.10 0.00 134 0.13 0.00 99.63 0.89 0.02 100 0.79 0.02 71 0.01 0.00 98 0.04 0.00 72.85 0.67 0.02 73 0.47 0.01 56 0.00 0.00 76 0.02 0.00 56.92 0.46 0.02 57 0.33 0.01 50 0.00 0.00 61 0.00 0.00 50 0.35 0.02 50 0.24 0.01 50 0.00 0.00 表 4 基于FHH模型计算微生物降解前后煤与泥页岩的分形维数结果

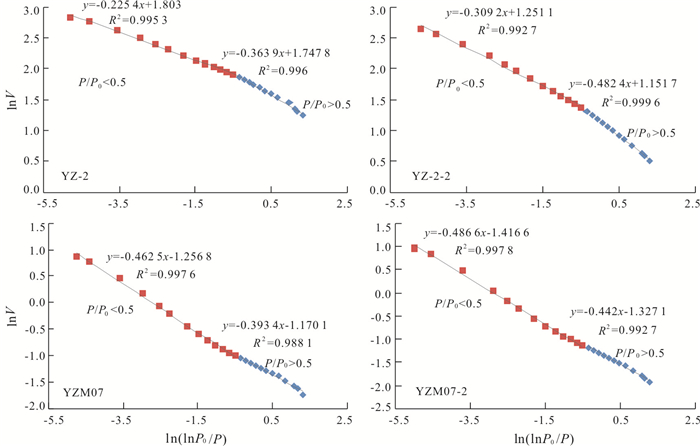

Table 4. Fractal dimensions derived from fractal FHH model

样品编号 P/P0=0~0.5 P/P0=0.5~1.0 吸附/脱附曲线类型a A1 D1 相关系数(R2) A2 D2 相关系数(R2) YZ-2 -0.225 4 2.774 6 0.995 3 -0.363 9 2.636 1 0.996 0 A类 YZ-2-2 -0.309 2 2.690 8 0.992 7 -0.482 4 2.517 6 0.999 6 A类 YZM07 -0.462 5 2.537 5 0.997 6 -0.393 4 2.606 6 0.988 1 A类 YZM07-2 -0.486 6 2.513 4 0.997 8 -0.442 0 2.558 0 0.992 7 A类 注:a存在吸附滞留环的A类与可逆等温线-不存在吸附滞留环的B类分类标准均为基于N2吸附脱附曲线数据所得. -

Bao, Y., Ju, Y. W., Wei, C. T., et al., 2015. Infrared Spectrum Studies of Hydrocarbon Generation and Structure Evolution of Peat Samples during Pyrolysis and Microbial Degradation. Spectroscopy and Spectral Analysis, 35(3): 603-608 (in Chinese with English abstract). Bao, Y., Wei, C. T., Neupane, B., 2016. Generation and Accumulation Characteristics of Mixed Coalbed Methane Controlled by Tectonic Evolution in Liulin CBM Field, Eastern Ordos Basin, China. Journal of Natural Gas Science and Engineering, 28: 262-270. https://doi.org/10.1016/j.jngse.2015.11.033 Bao, Y., Wei, C. T., Wang, C. Y., 2013. Geochemical Characteristics and Identification Significance of Coal Type Gas in Various Geneses. Earth Science, 38(5): 1037-1046 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/dqkx201305013 Bao, Y., Wei, C. T., Wang, C. Y., et al., 2013. Geochemical Characteristics and Identification of Thermogenic CBM Generated during the Low and Middle Coalification Stages. Geochemical Journal, 47(4): 451-458. https://doi.org/10.2343/geochemj.2.0265 Barrett, E. P., Joyner, L. G., Halenda, P. P., 1951. The Determination of Pore Volume and Area Distributions in Porous Substances.Ⅰ. Computations from Nitrogen Isotherms. Journal of the American Chemical Society, 73(1): 373-380. https://doi.org/10.1021/ja01145a126 Brunauer, S., Emmett, P. H., Teller, E., 1938. Adsorption of Gases in Multimolecular Layers. Journal of the American Chemical Society, 60(2): 309-319. https://doi.org/10.1021/ja01269a023 Cai, Y. D., Liu, D. M., Pan, Z. J., et al., 2013. Pore Structure and Its Impact on CH4 Adsorption Capacity and Flow Capability of Bituminous and Subbituminous Coals from Northeast China. Fuel, 103: 258-268. https://doi.org/10.1016/j.fuel.2012.06.055 Flores, R.M., 2014. Coal and Coalbed Gas: Fueling the Future. Elsevier, Waltham. Fripiat, J. J., Gatineau, L., van Damme, H., 1986. Multilayer Physical Adsorption on Fractal Surfaces. Langmuir, 2(5): 562-567. https://doi.org/10.1021/la00071a006 Fu, X. H., Deleqiati, J. N. T. Y., Zhu, Y. M., et al., 2016. Resources Characteristics and Separated Reservoirs' Drainage of Unconventional Gas in Coal Measures. Earth Science Frontiers, 23(3): 36-40 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/dxqy201603005 Groen, J. C., Peffer, L. A. A., Pérez-Ramı́rez, J., 2003. Pore Size Determination in Modified Micro- and Mesoporous Materials. Pitfalls and Limitations in Gas Adsorption Data Analysis. Microporous and Mesoporous Materials, 60(1-3): 1-17. https://doi.org/10.1016/s1387-1811(03)00339-1 Guo, H. Y., Luo, Y., Ma, J. Q., et al., 2014. Analysis of Mechanism and Permeability Enhancing Effect via Microbial Treatment on Different-Rank Coals. Journal of China Society, 39(9): 1886-1891 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/mtxb201409018 Ju, Y. W., Jiang, B., Hou, Q. L., et al., 2005. 13C NMR Spectra of Tectonic Coals and the Effects of Stress on Structural Components. Science in China (Series D), 35(9): 847-861 (in Chinese). doi: 10.1360%2F04yd0199 Katz, J. B., 2011. Microbial Processes and Natural Gas Accumulations. The Open Geology Journal, 5(1): 75-83. https://doi.org/10.2174/1874262901105010075 Klaver, J., Desbois, G., Urai, J. L., et al., 2012. BIB-SEM Study of the Pore Space Morphology in Early Mature Posidonia Shale from the Hils Area, Germany. International Journal of Coal Geology, 103: 12-25. https://doi.org/10.1016/j.coal.2012.06.012 Labani, M. M., Rezaee, R., Saeedi, A., et al., 2013. Evaluation of Pore Size Spectrum of Gas Shale Reservoirs Using Low Pressure Nitrogen Adsorption, Gas Expansion and Mercury Porosimetry: A Case Study from the Perth and Canning Basins, Western Australia. Journal of Petroleum Science and Engineering, 112: 7-16. https://doi.org/10.1016/j.petrol.2013.11.022 Loucks, R. G., Reed, R. M., Ruppel, S. C., et al., 2009. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. Journal of Sedimentary Research, 79(12): 848-861. https://doi.org/10.2110/jsr.2009.092 Loucks, R. G., Reed, R. M., Ruppel, S. C., et al., 2012. Spectrum of Pore Types and Networks in Mudrocks and a Descriptive Classification for Matrix-Related Mudrock Pores. AAPG Bulletin, 96(6): 1071-1098. https://doi.org/10.1306/08171111061 Lowell, S., Shields, J. E., Thomas, M. A., et al., 2004. Characterization of Porous Solid and Powders: Surface Area, Pore Size and Density. Springer, New York. Martini, A. M., Budai, J. M., Walter, L. M., et al., 1996. Microbial Generation of Economic Accumulations of Methane within a Shallow Organic-Rich Shale. Nature, 383(6596): 155-158. https://doi.org/10.1038/383155a0 Meng, Q., Wang, X. F., Wang, X. Z., et al., 2017. Gas Geochemical Evidences for Biodegradation of Shale Gases in the Upper Triassic Yanchang Formation, Ordos Basin, China. International Journal of Coal Geology, 179: 139-152. https://doi.org/10.1016/j.coal.2017.05.018 Nie, B. S., Lun, J. Y., Wang, K. D., et al., 2018. Characteristics of Nanometer Pore Structure in Coal Reservoir. Earth Science, 43(5): 1755-1762 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/dqkx201805034 Okolo, G. N., Everson, R. C., Neomagus, H. W. J. P., et al., 2015. Comparing the Porosity and Surface Areas of Coal as Measured by Gas Adsorption, Mercury Intrusion and SAXS Techniques. Fuel, 141: 293-304. https://doi.org/10.1016/j.fuel.2014.10.046 Rice, D. D., Claypool, G. E., 1981. Generation, Accumulation, and Resource Potential of Biogenic Gas. AAPG Bulletin, 65: 5-25. https://doi.org/10.1306/2f919765-16ce-11d7-8645000102c1865d Ross, D. J. K., Bustin, R. M., 2009. The Importance of Shale Composition and Pore Structure upon Gas Storage Potential of Shale Gas Reservoirs. Marine and Petroleum Geology, 26(6): 916-927. https://doi.org/10.1016/j.marpetgeo.2008.06.004 Scott, A. R., Kaiser, W. R., Ayers, J. W. B., 1994. Thermogenic and Secondary Biogenic Gases, San Juan Basin, Colorado and New Mexico-Implications for Coalbed Gas Producibility. AAPG Bulletin, 78: 1186-1209. https://doi.org/10.1306/a25feaa9-171b-11d7-8645000102c1865d Seaton, N. A., Walton, J. P. R. B., Quirke, N., 1989. A New Analysis Method for the Determination of the Pore Size Distribution of Porous Carbons from Nitrogen Adsorption Measurements. Carbon, 27(6): 853-861. https://doi.org/10.1016/0008-6223(89)90035-3 Shi, J. Q., Durucan, S., 2005. Gas Storage and Flow in Coalbed Reservoirs: Implementation of a Bidisperse Pore Model for Gas Diffusion in Coal Matrix. SPE Reservoir Evaluation & Engineering, 8(2): 169-175. https://doi.org/10.2118/84342-pa Sing, K. S. W., 1985. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and Porosity (Recommendations 1984). Pure and Applied Chemistry, 57(4): 603-619. https://doi.org/10.1351/pac198557040603 Song, Y., Jiang, B., Li, F. L., et al., 2018. Applicability of Fractal Models and Nanopores' Fractal Characteristics for Low-Middle Rank Tectonic Deformed Coals. Earth Science, 43(5): 1611-1622 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/dqkx201805022 Spitzer, Z., 1981. Mercury Porosimetry and Its Application to the Analysis of Coal Pore Structure. Powder Technology, 29(1): 177-186. https://doi.org/10.1016/0032-5910(81)85015-2 Strąpoć, D., Mastalerz, M., Dawson, K., et al., 2011. Biogeochemistry of Microbial Coal-Bed Methane. Annual Review of Earth and Planetary Sciences, 39(1): 617-656. https://doi.org/10.1146/annurev-earth-040610-133343 Tian, H., Zhang, S. C., Liu, S. B., et al., 2012. Determination of Organic-Rich Shale Pore Features by Mercury Injection and Gas Adsorption Methods. Acta Petrolei Science, 33(3): 419-427 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=syxb201203011 Wang, B. Y., Tai, C., Wu, L., et al., 2017a. Methane Production from Lignite through the Combined Effects of Exogenous Aerobic and Anaerobic Microflora. International Journal of Coal Geology, 173: 84-93. https://doi.org/10.1016/j.coal.2017.02.012 Wang, C. Y., Bao, Y., Wu, J., et al., 2017b. Pore Structure Differences between Underground and Outcrop of Palaeozoic Shales in the Upper Yangtze Platform, South China. Journal of Nanoscience and Nanotechnology, 17(9): 6803-6810. https://doi.org/10.1166/jnn.2017.14490 Yan, G. Y., Wei, C. T., Song, Y., et al., 2018. Quantitative Characterization of Shale Pore Structure Based on Ar-SEM and PCAS. Earth Science, 43(5): 1602-1610 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dqkx201805021 Yang, X. Q., Wu, R. W., Han, Z. Y., et al., 2017. Analysis of Methanogenic Community and Pathway of Coalbed Methane Fields in the Qinshui Basin Based on McrA Gene. Microbiology China, 44(4): 795-806 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wswxtb201704005 Yao, Y. B, Liu, D. M., Huang, W. H., et al., 2006. Research on the Pore-Fractures System Properties of Coalbed Methane Reservoirs and Recovery in Huainan and Huaibei Coal-Fields. Journal of China Coal Society, 31(2):163-168 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtxb200602007 Yao, Y. B., Liu, D. M., Tang, D. Z., et al., 2008. Fractal Characterization of Adsorption-Pores of Coals from North China: An Investigation on CH4 Adsorption Capacity of Coals. International Journal of Coal Geology, 73(1): 27-42. https://doi.org/10.1016/j.coal.2007.07.003 Yao, Y. B., Liu, D. M., Tang, D. Z., et al., 2009. Fractal Characterization of Seepage-Pores of Coals from China: An Investigation on Permeability of Coals. Computers & Geosciences, 35(6): 1159-1166. https://doi.org/10.1016/j.cageo.2008.09.005 Yin, Y., 1991. Adsorption Isotherm on Fractally Porous Materials. Langmuir, 7(2): 216-217. https://doi.org/10.1021/la00050a002 鲍园, 琚宜文, 韦重韬, 等, 2015.热解和生物降解对木本泥炭生烃与结构演化的红外光谱响应.光谱学与光谱分析, 35(3): 603-608. doi: 10.3964/j.issn.1000-0593(2015)03-0603-06 鲍园, 韦重韬, 王超勇, 2013.不同成因类型煤型气地球化学特征及其判识意义.地球科学, 38(5): 1037-1046. doi: 10.3799/dqkx.2013.101 傅雪海, 德勒恰提·加纳塔依, 朱炎铭, 等, 2016.煤系非常规天然气资源特征及分隔合采技术.地学前缘, 23(3): 36-40. http://d.old.wanfangdata.com.cn/Periodical/dxqy201603005 郭红玉, 罗源, 马俊强, 等, 2014.不同煤阶煤的微生物增透效果和机理分析.煤炭学报, 39(9): 1886-1891. http://d.old.wanfangdata.com.cn/Periodical/mtxb201409018 琚宜文, 姜波, 侯泉林, 等, 2005.构造煤13C NMR谱及其结构成分的应力效应.中国科学(D辑), 35(9): 847-861. http://d.old.wanfangdata.com.cn/Periodical/zgkx-cd200509005 聂百胜, 伦嘉云, 王科迪, 等, 2018.煤储层纳米孔隙结构及其瓦斯扩散特征.地球科学, 43(5): 1755-1762. doi: 10.3799/dqkx.2018.427 宋昱, 姜波, 李凤丽, 等, 2018.低-中煤级构造煤纳米孔分形模型适用性及分形特征.地球科学, 43(5): 1611-1622. doi: 10.3799/dqkx.2017.566 田华, 张水昌, 柳少波, 等, 2012.压汞法和气体吸附法研究富有机质页岩孔隙特征.石油学报, 33(3): 419-427. http://d.old.wanfangdata.com.cn/Periodical/syxb201203011 闫高原, 韦重韬, 宋昱, 等, 2018.基于Ar-SEM及PCAS页岩孔隙结构定量表征.地球科学, 43(5): 1602-1610. doi: 10.3799/dqkx.2017.525 杨秀清, 吴瑞薇, 韩作颖, 等, 2017.基于mcrA基因的沁水盆地煤层气田产甲烷菌群与途径分析.微生物学通报, 44(4): 795-806. http://d.old.wanfangdata.com.cn/Periodical/wswxtb201704005 姚艳斌, 刘大锰, 黄文辉, 等, 2006.两淮煤田煤储层孔-裂隙系统与煤层气产出性能研究.煤炭学报, 31(2):163-168. doi: 10.3321/j.issn:0253-9993.2006.02.007 -

下载:

下载: