Micromorphology and Structure Changes of Microcrystalline Graphite during Process of Oxidation and Expansion

-

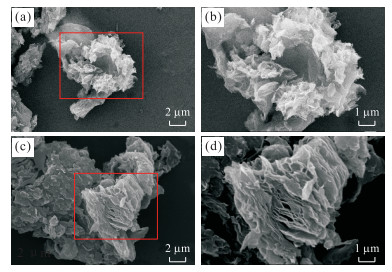

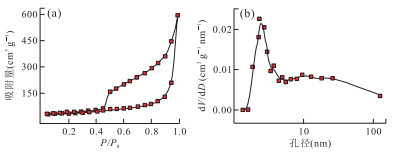

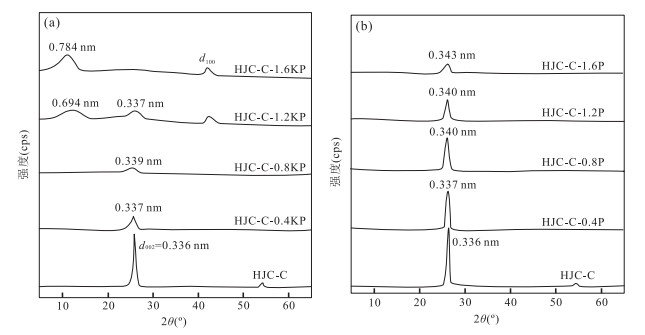

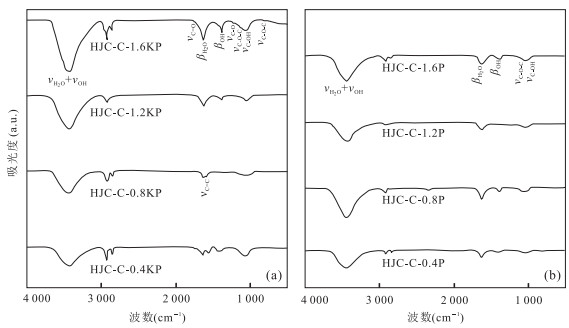

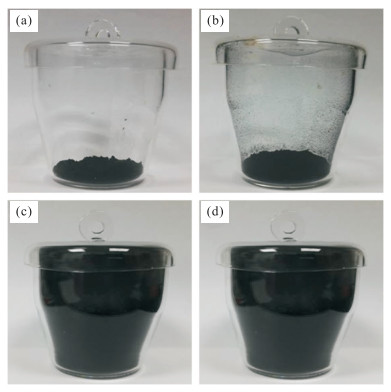

摘要: 为深度揭示微晶石墨氧化和膨胀过程中结构的变化规律,分别采用SEM-EDS、XRD、Raman和FTIR等测试分析手段对其产物结构进行表征研究.结果表明:微晶石墨经氧化后,层间域被撑大,结构层上接入大量的羟基、羧基和环氧基等亲水性含氧官能团.随氧化剂(KMnO4)用量增加,产物层间距、结构缺陷和无序度逐渐增大.高温膨胀后,氧化微晶石墨被还原,结构中的部分吸附水和含氧官能团被除去,结构缺陷与无序度减小,部分sp2区域得到了恢复.膨胀微晶石墨颗粒含有丰富的网络型孔隙结构,孔径集中在2~5 nm.Abstract: In order to reveal the structure changes of microcrystalline graphite in the process of oxidation and expansion, the products were characterized by means of SEM-EDS, XRD, Raman and FTIR in this study. The results show that the interlayer distance of microcrystalline graphite oxide is enlarged and many functional groups including hydroxyl, carboxyl and epoxy groups are bonded on the graphene layer in the oxidation process. In addition, with the increase of oxidant (KMnO4), the space distance, structural defects and disorder of oxidized product increased gradually. After being expanded with high temperature, some of the oxygen-containing functional groups in the structure were removed, and the oxidized microcrystalline graphite was reduced partly. In addition, the structural defects and disorder degrees of expanded microcrystalline graphite reduced, and local sp2 regions were recovered. The expanded microcrystalline graphite particles contained abundant network pore structures with pore sizes of 2-5 nm.

-

Key words:

- microcrystalline graphite /

- oxidation /

- expansion /

- structure /

- mineralogy

-

表 1 各膨胀微晶石墨样品的比表面积和孔容

Table 1. The specific surface areas and pore capacity of expanded microcrystalline graphite samples

样品名称 BET比表面积(m2/g) 孔容(cm3/g) 平均孔径(nm) HJC-C-0.4P 59.88 — — HJC-C-0.8P 65.89 — — HJC-C-1.2P 137.53 — — HJC-C-1.6P 189.75 1.02 29.33 注:“—”表示未检测. 表 2 样品的FTIR谱图中官能团类型及波数

Table 2. The type of functional group and the wavenumbers in the FTIR

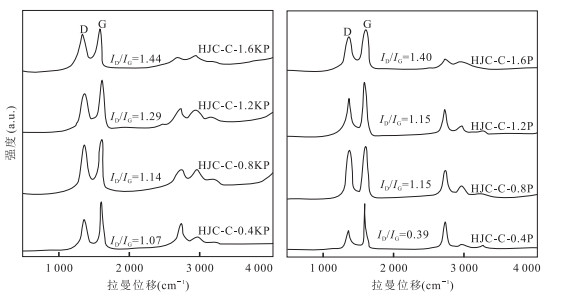

官能团类型 C-OH C=C C=O C-O C-O-C H2O(OH) ν β ν ν ν ν ν β 波数(cm-1) 1 048, 1 090 1 384 1 578, 1 462 1 739 1 270 880, 1 120 3 434 1 631 表 3 HJC-C-nKP系列和HJC-C-nP系列样品的Raman光谱参数

Table 3. Raman spectral parameters of HJC-C-nKP and HJC-C-nP samples

样品编号 D峰(cm-1) G峰(cm-1) 峰间距(cm-1) ID/IG 峰位 半峰宽 峰位 半峰宽 HJC-C 1 352.21 38.01 1 581.53 22.00 229.32 0.43 HJC-C-0.4KP 1 350.05 86.45 1 589.12 47.78 239.07 1.07 HJC-C-0.8KP 1 349.50 93.30 1 590.34 52.27 240.84 1.14 HJC-C-1.2KP 1 351.20 115.96 1 589.39 65.75 238.19 1.29 HJC-C-1.6KP 1 354.96 130.20 1 587.16 74.78 232.20 1.44 HJC-C-0.4P 1 356.43 70.79 1 583.27 30.92 226.84 0.88 HJC-C-0.8P 1 356.61 69.51 1 589.80 54.40 233.19 1.15 HJC-C-1.2P 1 355.10 89.74 1 586.34 54.18 231.24 1.15 HJC-C-1.6P 1 355.29 123.53 1 588.52 67.38 233.23 1.40 -

Acik, M., Lee, G., Mattevi, C., et al., 2011.The Role of Oxygen during Thermal Reduction of Graphene Oxide Studied by Infrared Absorption Spectroscopy.The Journal of Physical Chemistry C, 115(40):19761-19781. https://doi.org/10.1021/jp2052618 Blechta, V., Mergl, M., Drogowska, K., et al., 2016.NO2 Sensor with a Graphite Nanopowder Working Electrode.Sensors & Actuators B:Chemical, 226:299-304. https://doi.org/10.1016/j.snb.2015.11.130 Bourlinos, A.B., Gournis, D., Petridis, D., et al., 2003.Graphite Oxide:Chemical Reduction to Graphite and Surface Modification with Primary Aliphatic Amines and Amino Acids.Langmuir, 19(15):6050-6055. https://doi.org/10.1021/la026525h Duan, J.Q., Sun, H.J., Peng, T.J., 2017.Purification of Microcrystalline Graphite by Ultrasonic Treatment and Mixed Acid.Non-Metallic Mines, 40(1):58-61 (in Chinese with English abstract). doi: 10.1080/01496395.2016.1206933 Fang, Q., Hong, H.L., Zhao, L.L., et al., 2018.Climatic Implication of Authigenic Minerals Formed during Pedogenic Weathering Processes.Earth Science, 43(3):753-769 (in Chinese with English abstract). https://doi.org/10.3799/dqkx.2018.905 Feng, M.Z., Peng, T.J., Sun, H.J., at al., 2016.Effect of Oxidation Degree on Structure and Cation Exchange Capacity of Graphite Oxide.Chinese Journal of Inorganic Chemistry, 32(3):427-433 (in Chinese with English abstract). doi: 10.1021/jp027500u Jian, Z.M., Liu, H.B., Kuang, J.C., et al., 2012.Natural Flake Graphite Modified by Mild Oxidation and Carbon Coating Treatment as Anode Material for Lithium Ion Batteries.Procedia Engineering, 27:55-62. https://doi.org/10.1016/j.proeng.2011.12.424 Kim, H.M., Kim, K.M., Lee, K.H., et al., 2012.Nano-Bio Interaction between Graphite Oxide Nanoparticles and Human Blood Components.European Journal of Inorganic Chemistry, (32):5343-5349. https://doi.org/10.1002/ejic.201200587 Kim, K.J., Lee, T.S., Kim, H.G., et al., 2014.A Hard Carbon/Microcrystalline Graphite/Carbon Composite with a Core-Shell Structure as Novel Anode Materials for Lithium-Ion Batteries.Electrochimica Acta, 135(22):27-34. https://doi.org/10.1016/j.electacta.2014.04.171 Kuan, C.F., Tsai, K.C., Chen, C.H., et al., 2012.Preparation of Expandable Graphite via H2O2-Hydrothermal Process and Its Effect on Properties of High-Density Polyethylene Composites.Polymer Composites, 33(6):872-880. https://doi.org/10.1002/pc.22224 Lin, Y.X., Huang, Z.H., Yu, X.L., et al., 2014.Mildly Expanded Graphite for Anode Materials of Lithium Ion Battery Synthesized with Perchloric Acid.Electrochimica Acta, 116(2):170-174. https://doi.org/10.1016/j.electacta.2013.11.057 Malliga, T.V., Rajasekhar, R.V.J., 2017.Preparation and Characterization of Nanographite-and Cuo-Based Absorber and Performance Evaluation of Solar Air-Heating Collector.Journal of Thermal Analysis & Calorimetry, 129(1):233-240. https://doi.org/10.1007/s10973-017-6155-1 McAllister, M.J., Li, J.L., Adamson, D.H., et al., 2007.Single Sheet Functionalized Graphene by Oxidation and Thermal Expansion of Graphite.Chemistry of Materials, 19(18):4396-4404. https://doi.org/10.1021/cm0630800 Pang, X.Y., Tian, Y., Weng, M.Q., 2015.Preparation of Expandable Graphite with Silicate Assistant Intercalation and Its Effect on Flame Retardancy of Ethylene Vinyl Acetate Composite.Polymer Composites, 36(8):1407-1416. https://doi.org/10.1002/pc.23047 Park, S., Lee, K.S., Bozoklu, G., et al., 2008.Graphene Oxide Papers Modified by Divalent Ions-Enhancing Mechanical Properties via Chemical Cross-Linking.ACS Nano, 2(3):572-578. https://doi.org/10.1021/nn700349a Park, T.H., Yeo, J.S., Seo, M.H., et al., 2013.Enhancing the Rate Performance of Graphite Anodes through Addition of Natural Graphite/Carbon Nanofibers in Lithium-Ion Batteries.Electrochimica Acta, 93:236-240. https://doi.org/10.1016/j.electacta.2012.12.124 Pielichowska, K., Bieda, J., Szatkowski, P., 2016.Polyurethane/Graphite Nano-Platelet Composites for Thermal Energy Storage.Renewable Energy, 91:456-465. https://doi.org/10.1016/j.renene.2016.01.076 Saji, J., Khare, A., Mahapatra, S.P., 2015.Impedance and Dielectric Spectroscopy of Nano-Graphite Reinforced Silicon Elastomer Nanocomposites.Fibers & Polymers, 16(4):883-893. https://doi.org/10.1007/s12221-015-0883-2 She, Z., Yang, F., Liu, W., et al., 2016.The Termination and Aftermath of the Lomagundi-Jatuli Carbon Isotope Excursions in the Paleoproterozoic Hutuo Group, North China.Journal of Earth Science, 27(2):297-316. https://doi.org/10.1007/s12583-015-0654-4 Shen, K., Huang, Z.H., Hu, K.X., et al., 2015.Advantages of Natural Microcrystalline Graphite Filler over Petroleum Coke in Isotropic Graphite Preparation.Carbon, 90:197-206. https://doi.org/10.1016/j.carbon.2015.03.068 Strom, T.A., Dillon, E.P., Hamilton, C.E., et al., 2010.Nitrene Addition to Exfoliated Graphene:A One-Step Route to Highly Functionalized Graphene.Chemical Communications, 46(23):4097-4099. https://doi.org/10.1039/C001488E Wang, J., Huang, J., Yan, R., et al., 2015.Graphene Microsheets from Natural Microcrystalline Graphite Minerals:Scalable Synthesis and Unusual Energy Storage.Journal of Materials Chemistry A, 3(6):3144-3150. https://doi.org/10.1039/C4TA06332E Wang, J.J., Li, G.Z., Feng, L.J., et al., 2017.Nano-Graphite Controlling Properties of Novel Composites with Damping-Absorption Functions and Storage-Loss Behaviors:Nano-Graphite/Pzt-Pmn-Pnn/Rtv.Current Applied Physics, 17(2):130-136. https://doi.org/10.1016/j.cap.2016.11.019 Xian, H.Y., Peng, T.J., Sun, H.J., et al., 2015.Mineralogical Characteristics of Some Typical Graphite Samples in China.Acta Mineralogica Sinica, 35(3):395-405(in Chinese with English abstract). http://www.journalssystem.com/ppmp/Mineralogical-characteristics-of-metallurgical-dust-in-the-vicinity-of-Glogow,79500,0,2.html Xian, H.Y., Peng, T.J., Sun, H.J., et al., 2015.Preparation, Characterization and Supercapacitive Performance of Graphene Nanosheets from Microcrystalline Graphite.Journal of Materials Science Materials in Electronics, 26(1):242-249. https://doi.org/10.1007/s10854-014-2391-3 Xu, L.L., Jin, Z.M., Mei, S.H., 2017.Deformation-DIA Coupled with Synchrotron X-Ray Diffraction and Its Applications to Deformation Experiments of Minerals at High Temperature and High Pressure.Earth Science, 42(6):974-989 (in Chinese with English abstract). https://doi.org/10.3799/dqkx.2017.078 Ying, Z.R., Lin, X.M., Qi, Y., et al., 2008.Preparation and Characterization of Low-Temperature Expandable Graphite.Materials Research Bulletin, 43(10):2677-2686. https://doi.org/10.1016/j.materresbull.2007.10.027 Zhang, B., Li, F., Wu, T., et al., 2015.Adsorption of P-Nitrophenol from Aqueous Solutions Using Nanographite Oxide.Colloids & Surfaces A:Physicochemical & Engineering Aspects, 464:78-88. https://doi.org/10.1016/j.colsurfa.2014.10.020 Zhang, F.S., Zhao, Q., Yan, X., et al., 2016.Rapid Preparation of Expanded Graphite by Microwave Irradiation for the Extraction of Triazine Herbicides in Milk Samples.Food Chemistry, 197:943-949. https://doi.org/10.1016/j.foodchem.2015.11.056 段佳琪, 孙红娟, 彭同江, 2017.超声-混酸法提纯微晶石墨.非金属矿, 40(1):58-61. http://www.cnki.com.cn/Article/CJFDTotal-TSJS201405009.htm 方谦, 洪汉烈, 赵璐璐, 等, 2018.风化成土过程中自生矿物的气候指示意义.地球科学, 43(3):753-769. http://www.earth-science.net/WebPage/Article.aspx?id=3766 冯明珠, 彭同江, 孙红娟, 等, 2016.氧化程度对氧化石墨结构与阳离子交换容量的影响.无机化学学报, 32(3):427-433. doi: 10.11862/CJIC.2016.047 鲜海洋, 彭同江, 孙红娟, 等, 2015.我国若干典型石墨矿山石墨的矿物学特征.矿物学报, 35(3):395-405. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_kwxb201503017 许丽丽, 金振民, Mei, S.H., 2017.D-DIA装置与同步辐射源结合技术及其在矿物高温高压变形实验中的应用.地球科学, 42(6):974-989. http://www.earth-science.net/WebPage/Article.aspx?id=3591 -

下载:

下载: