Experiments on Friction and Non-Steady Slip for Shale

-

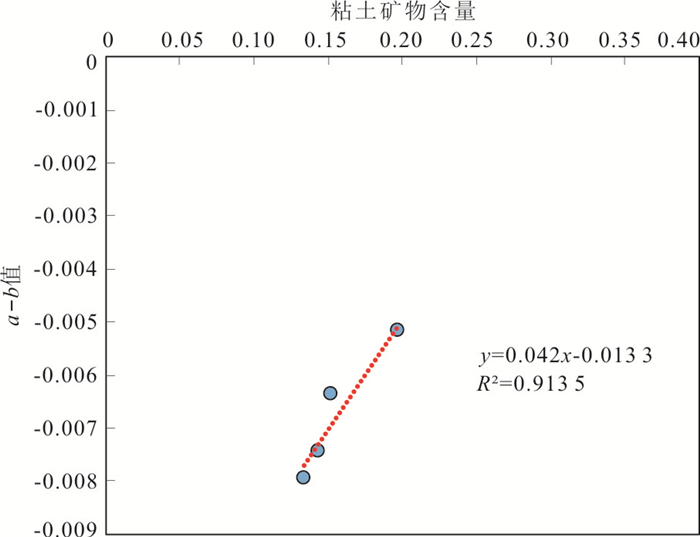

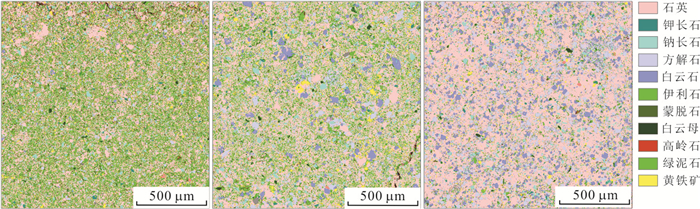

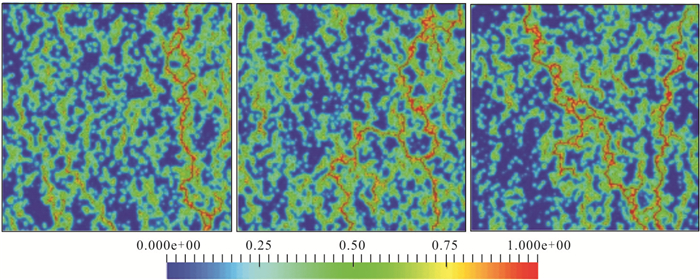

摘要: 龙一1亚段页岩是川南页岩气开发的主要目的层,实践表明水平井单井产气量对井轨迹所在小层较为敏感.龙一1亚段页岩各层脆性矿物组分、弹性模量变化幅度小,采用常规页岩脆性评价方法和模型不能有效评价川南龙一1亚段各小层页岩的可压性,借鉴地震学地震成核原因研究思路,提出利用稳态-非稳态破坏特征来表征各小层可压性.优化设计一种页岩剪切摩擦、稳态-非稳态特性实验方法,利用川南页岩地面露头进行线切割制样开展相关实验测试,分析研究页岩摩擦系数受层理性构造、矿物组分、法向应力大小的影响,表征量化不同矿物组分下的页岩稳态-非稳态特征,确定了速度弱化向速度强化转换的粘土矿物含量临界值.以川南昭通YS108井区龙一1亚段页岩储层为例,对各小层可压性进行整体评价,得到:龙一11~2层较易开启剪切滑移,且易形成网状裂纹,储层整体可压性好;龙一13层较难开启剪切滑移,但裂纹为单一裂纹、网状裂纹过渡状态,储层整体可压性较差;龙一14层较易开启剪切滑移,但裂纹则呈现单一状态,储层整体可压性较差.Abstract: L11 sub-section shale reservoir is the major production layer in the South Sichuan shale gas block. For the horizontal well production, different well paths in the different layers can show quite big production gap, which may be due to the different shale crushabilities. However, the elastic modulus and brittle minerals for different layers in L11 sub-section have not shown much difference, so it is still impossible to evaluate the shale brittleness sufficiently with the conventional methods and models, Based on studies on the cause of earthquake, the steady & non-steady state failure is introduced to characterize the crushability for the different L11 layers in this paper. The new friction and steady & non-steady state experiments were designed to replace the conventional fault gauge testing method for the L11 outcrop samples. Firstly, the influence of the lamination, mineral constituents and normal stress on the friction for shale was studied and analyzed. Secondly, the steady & non-steady state behavior was characterized and quantified by the calculated a-b value for the shale with different mineral constituents. Thirdly, the critical value from velocity-weakening to velocity-strengthening was established by the overlay method. Taking Well YS108 field in Zhaotong shale block as the example, the different crushabilities for different layers were analyzed and discussed. It is found that L111-2 layers have better crushability that can cause the shear slide easily and generate the map cracking, while the L114 layers have worse crushability that generates the single cracking or cause the shear slide difficultly.

-

Key words:

- shale /

- friction /

- steady state /

- non-steady state /

- crushability /

- petroleum geology

-

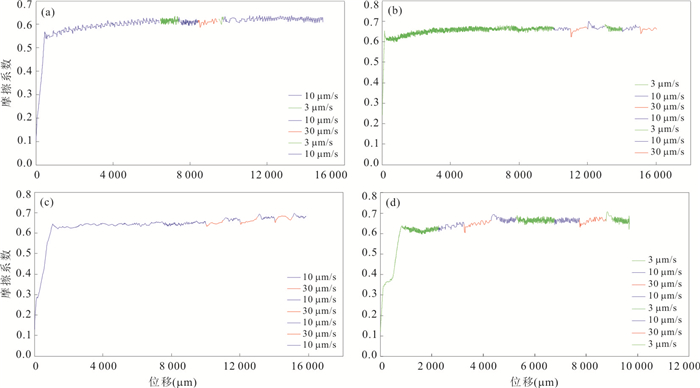

图 6 五峰组和龙马溪组平行层理、垂直层理页岩在不同水平应力加载速度下的摩擦系数-位移曲线

a.五峰组平行层理页岩在不同水平应力加载速度下的摩擦系数-位移曲线; b.五峰组垂直层理页岩在不同水平应力加载速度下的摩擦系数-位移曲线; c.龙马溪组平行层理页岩在不同水平应力加载速度下的摩擦系数-位移曲线; d.龙马溪组垂直层理页岩在不同水平应力加载速度下的摩擦系数-位移曲线

Fig. 6. The testing plots between friction factor and displacement in different loading velocities for the parallel and vertical bedding samples from Wufeng Formation and Longmaxi Formation

表 1 四组试样全岩矿物XRD衍射测试数据

Table 1. The whole-rock analysis data of the four shale samples by XRD diffraction

组别 矿物种类和含量(%) 粘土矿物总量(%) 石英 钾长石 斜长石 黄铁矿 脆性矿物 白云石 方解石 碳酸盐岩矿物 五峰平行 27.9 0.4 2.2 3.4 33.9 13.6 39.1 52.7 13.4 五峰垂直 28.6 0.6 4.3 2.4 35.9 11.4 38.3 49.7 14.4 龙马溪平行 33.3 0.2 4.9 3.7 42.1 12.6 25.5 38.1 19.8 龙马溪垂直 38.3 0.5 5.0 4.3 48.1 9.2 27.4 36.6 15.3 表 2 五峰组平行层理页岩的a-b值计算表

Table 2. The values of a-b for the parallel bedding shale from Wufeng Formation

速度(μm/s) 摩擦系数 a-b 10 0.616 / 3 0.616 0 10 0.610 -0.004 98 30 0.610 0 3 0.630 -0.008 69 10 0.622 -0.006 64 平均值 -0.007 95 表 3 五峰组垂直层理页岩的a-b值计算表

Table 3. The values of a-b for the vertical bedding shale from Wufeng Formation

速度(μm/s) 摩擦系数 a-b 3 0.675 / 10 0.668 -0.005 81 30 / / 10 / / 3 / / 10 0.672 / 30 0.662 -0.009 1 平均值 -0.007 46 表 4 龙马溪组平行层理页岩的a-b值计算表

Table 4. The values of a-b for the parallel bedding shale from Longmaxi Formation

速度(μm/s) 摩擦系数 a-b 10 0.643 / 30 0.640 -0.002 73 10 0.649 -0.008 19 30 0.644 -0.004 55 10 / / 30 / / 10 / / 平均值 -0.005 16 表 5 龙马溪组垂直层理页岩的a-b值计算表

Table 5. The values of a-b for the vertical bedding shale from Longmaxi Formation

速度(μm/s) 摩擦系数 a-b 10 0.663 / 30 0.663 0 10 0.670 -0.006 37 3 0.670 0 10 0.670 0 30 0.670 0 3 0.670 0 平均值 -0.006 37 表 6 YS108井区龙一1亚段地应力状态

Table 6. The crustal stress state of L11 sub-section in the YS108 well block

井区 小层 顶深(m) 底深(m) Sv(g/cm3) Shmax(g/cm3) Shmin(g/cm3) 水平地应力非均匀系数 YS108 龙一14 2 483.52 2 495.70 2.52 2.98 2.26 0.32 龙一13 2 495.70 2 502.78 2.52 2.75 2.22 0.24 龙一12 2 502.78 2 509.54 2.52 3.15 2.31 0.36 龙一11 2 509.54 2 511.01 2.53 3.10 2.32 0.34 五峰 2 511.01 2 516.05 2.52 3.06 2.39 0.28 -

Das, I., Zoback, M.D., 2011. Long-Period, Long-Duration Seismic Events during Hydraulic Fracture Stimulation of a Shale Gas Reservoir. The Leading Edge, 30(7):778-786. https://doi.org/10.1190/1.3609093 Das, I., Zoback, M.D., 2012. Microearthquakes Associated with Long Period, Long Duration Seismic Events during Stimulation of a Shale Gas Reservoir. 2012 SEG Annual Meeting, Las Vegas. Dieterich, J.H., 1978. Time-Dependent Friction and the Mechanics of Stick-Slip. Pure and Applied Geophysics, 116(4/5): 790-806. https://doi.org/10.1007/bf00876539 Dieterich, J.H., 1979. Modeling of Rock Friction: 1. Experimental Results and Constitutive Equations. Journal of Geophysical Research, 84(B5): 2161-2168. https://doi.org/10.1029/jb084ib05p02161 Elsworth, D., 2017. Deformation and Permeability Evolution in Reservoir and Seals with a Focus on Well Survivability. Shale Gas Engineering Geomechanics International Conference, Beijing. Jiang, T.X., Bian, X.B., Su, Y., et al., 2014. A New Method for Evaluating Shale Fracability Index and Its Application. Petroleum Drilling Techniques, 42(5): 16-20 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=syztjs201405003 Jiang, Z.X., Duan, H.J., Liang, C., et al., 2017.Classification of Hydrocarbon-Bearing Fine-Grained Sedimentary Rocks. Journal of Earth Science, 28(6):963-976. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dqkx-e201706001 Li, J.Q., Zhang, P.F., Lu, S.F., et al., 2019. Scale-Dependent Nature of Porosity and Pore Size Distribution in Lacustrine Shales: An Investigation by BIB-SEM and X-Ray CT Methods. Journal of Earth Science, 30(4):823-833. doi: 10.1007/s12583-018-0835-z Li, Q.H., Chen, M., Jin, Y., 2012a. Experimental Research on Failure Modes and Mechanical Behaviors of Gas-Bearing Shale. Chinese Journal of Rock Mechanics and Engineering, 31(S2): 3763-3771 (in Chinese with English abstract). http://cn.bing.com/academic/profile?id=80a36d4bbfbba9aec1d0442bb0f137e6&encoded=0&v=paper_preview&mkt=zh-cn Li, Q.H., Chen, M., Jin, Y., et al., 2012b. Rock Mechanical Properties and Brittleness Evaluation of Shale Gas Reservoir. Petroleum Drilling Techniques, 40(4): 17-22 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/gcdzxb201706004 Li, W.Y., Zou, H.L., Wu, C.Z., et al., 2013. An Analysis of Shale Gas Development in View of Engineering Technologies. Acta Petrolei Sinica, 34(6): 1218-1224 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=syxb201306026 Li, Z., Jiang, Z.X., Tang, X.L., et al., 2017. Lithofacies Characteristics and Its Effect on Pore Structure of the Marine Shale in the Low Silurian Longmaxi Formation, Southeastern Chongqing. Earth Science, 42(7): 1116-1123 (in Chinese with English abstract). https://doi.org/10.3799/dqkx.2017.090 Liang, X., Wang, G.C., Xu, Z.Y., et al., 2016. Comprehensive Evaluation Technology for Shale Gas Sweet Spots in the Complex Marine Mountains, South China: A Case Study from Zhaotong National Shale Gas Demonstration Zone. Natural Gas Industry, 36(1): 33-42 (in Chinese with English abstract). http://www.sciencedirect.com/science/article/pii/S2352854016300122 Lu, B.P., 2013. SINOPEC Engineering Technical Advance and Its Developing Tendency in Shale Gas. Petroleum Drilling Techniques, 41(5): 1-8 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=syztjs201305001 Mulen, M., Enderlin, M., 2012. Fracability Index-More than just Calculating Rock Properties. SPE Annual Technical Conferenceand Exhibition, San Antonio. https: //doi.org/10.2118/159755-MS Palmer, I.D., Moschovidis, Z.A., Cameron, J.R., 2007. Modeling Shear Failure and Stimulation of the Barnett Shale after Hydraulic Fracturing. SPE Hydraulic Fracturing Technology Conference, Texas. Simpson, R.W., 1997. Quantifying Anderson's Fault Types. Journal of Geophysical Research: Solid Earth, 102(B8):17909-17919. https://doi.org/10.1029/97jb01274 Wu, Q., Xu, Y., Zhang, S.L., et al., 2014.The Core Theories and Key Optimization Designs of Volume Stimulation Technology for Unconventional Reservoirs. Acta Petrolei Sinica, 35(4):706-714 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=syxb201404011 Xu, Y., Lei, Q., Chen, M., et al., 2018.Progress and Development of Volume Stimulation Techniques. Petroleum Exploration and Development, 45(5):874-887 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/syktykf201805014 Yang, H.L., Qiao, L., Tian, Z.L., 2017. Advances in Shale Gas Reservoir Engineering and Geomechanics Integration Technology and Relevant Discussions. Petroleum Drilling Techniques, 45(2):25-31 (in Chinese with English abstract). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=syztjs201702005 Yang, H.L., Zhang, J.J., Wang, G.C., et al., 2018. Fabric Difference and Mineral Nanomechanics Characteristics of High-Quality Shale in Longmaxi Formation, Weiyuan Block in Sichuan Basin and Zhaotong Block in Yunnan Province. Natural Gas Exploration and Development, 41(1):16-22 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/trqktykf201801004 Yao, X.X., 1984. The Experimental Studies of Stable and Unstable Cracking by Using a Ultrasmall Testing Machine. Acta Geophysica Sinica, 27(5):439-445 (in Chinese with English abstract). http://cn.bing.com/academic/profile?id=2282abed8e635cb1891029437739a097&encoded=0&v=paper_preview&mkt=zh-cn Yuan, J.L., Deng, J.G., Zhang, D.Y., et al., 2013. Fracability Evaluation of Shale-Gas Reservoirs. Acta Petrolei Sinica, 34(3): 523-527 (in Chinese with English abstract). http://d.old.wanfangdata.com.cn/Periodical/dkyqt201801016 Yue, P.S., Shi, Q., Yue, L.Q., et al., 2017. The Latest Progress of Shale Gas Exploration and Development in China. Natural Gas Exploration and Development, 40(3):38-44 (in Chinese with English abstract). http://cn.bing.com/academic/profile?id=12368d33ed14a61e57dce360c8117275&encoded=0&v=paper_preview&mkt=zh-cn Zhang, S.C., 2017. Research on the Rule of Crack Propagation during Hydraulic Fracturing in Shale Gas Reservoir (Dissertation). Liaoning Technical University, Fuxin, 82-86 (in Chinese with English abstract). Zhu, R.K., Jin, X., Wang, X.Q., et al., 2018. Multi-Scale Digital Rock Evaluation on Complex Reservoir. Earth Science, 43(5):1773-1782 (in Chinese with English abstract). https://doi.org/10.3799/dqkx.2018.429 Zoback, M.D., Kohli, A., Das, I., et al., 2012. The Importance of Slow Slip on Faults during Hydraulic Fracturing Stimulation of Shale Gas Reservoirs. SPE Americas Unconventional Resources Conference, Pittsburgh. https: //doi.org/10.2118/155476-MS Zou, C.N., Dong, D.Z., Wang, Y. M., et al., 2016. Shale Gas in China: Characteristics, Challenges and Prospects (Ⅱ). Petroleum Exploration and Development, 43(2):166-178(in Chinese with English abstract). http://en.cnki.com.cn/Article_en/CJFDTotal-SKYK201602003.htm 蒋廷学, 卞晓冰, 苏瑗, 等, 2014.页岩可压性指数评价新方法及应用.石油钻探技术, 42(5): 16-20. http://d.old.wanfangdata.com.cn/Periodical/syztjs201405003 李庆辉, 陈勉, 金衍, 2012a.含气页岩破坏模式及力学特性的试验研究.岩石力学与工程学报, 31(S2): 3763-3771. http://www.cnki.com.cn/Article/CJFDTotal-YSLX2012S2044.htm 李庆辉, 陈勉, 金衍, 等, 2012b.页岩气储层岩石力学特性及脆性评价.石油钻探技术, 40(4): 17-22. http://d.old.wanfangdata.com.cn/Periodical/syztjs201204004 李文阳, 邹洪岚, 吴纯忠, 等, 2013.从工程技术角度浅析页岩气的开采.石油学报, 34(6): 1218-1224. http://d.old.wanfangdata.com.cn/Periodical/syxb201306026 李卓, 姜振学, 唐相路, 等, 2017.渝东南下志留统龙马溪组页岩岩相特征及其对孔隙结构的控制.地球科学, 42(7): 1116-1123. doi: 10.3799/dqkx.2017.090 梁兴, 王高成, 徐政语, 等, 2016.中国南方海相复杂山地页岩气储层甜点综合评价技术——以昭通国家级页岩气示范区为例.天然气工业, 36(1):33-42. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=trqgy201601004 路保平, 2013.中国石化页岩气工程技术进步及展望.石油钻探技术, 41(5): 1-8. doi: 10.3969/j.issn.1001-0890.2013.05.001 吴奇, 胥云, 张守良, 等, 2014.非常规油气层体积改造技术核心理论与优化设计关键.石油学报, 35(4):706-714. http://www.cnki.com.cn/Article/CJFDTotal-SYXB201404011.htm 胥云, 雷群, 陈铭, 等, 2018.体积改造技术理论研究进展与发展方向.石油勘探与开发, 45(5):874-887. http://d.old.wanfangdata.com.cn/Periodical/syktykf201805014 杨恒林, 乔磊, 田中兰, 2017.页岩气储层工程地质力学一体化技术进展与探讨.石油钻探技术, 45(2):25-31. http://d.old.wanfangdata.com.cn/Periodical/syztjs201702005 杨恒林, 张俊杰, 王高成, 等, 2018.四川威远及云南昭通区块龙马溪组优质页岩组构差异性与矿物纳米力学特征.天然气勘探与开发, 41(1):16-22. http://d.old.wanfangdata.com.cn/Periodical/trqktykf201801004 姚孝新, 1984.用超小型压力机研究裂纹的稳态与非稳态扩展.地球物理学报, 27(5):439-445. doi: 10.3321/j.issn:0001-5733.1984.05.004 袁俊亮, 邓金根, 张定宇, 等, 2013.页岩气储层可压裂性评价技术.石油学报, 34(3): 523-527. http://d.old.wanfangdata.com.cn/Periodical/syxb201303015 岳鹏升, 石乔, 岳来群, 等, 2017.中国页岩气近期勘探开发进展.天然气勘探与开发, 40(3): 38-44. http://d.old.wanfangdata.com.cn/Periodical/trqktykf201703007 张树翠, 2017.页岩气储层水力压裂裂纹扩展规律研究(博士学位论文).阜新: 辽宁工程技术大学, 82-86. http://cdmd.cnki.com.cn/Article/CDMD-10147-1018261624.htm 朱如凯, 金旭, 王晓琦, 等, 2018.复杂储层多尺度数字岩石评价.地球科学, 43(5):1773-1782. doi: 10.3799/dqkx.2018.429 邹才能, 董大忠, 王玉满, 等, 2016.中国页岩气特征、挑战及前景(二).石油勘探与开发, 43(2):166-178. doi: 10.11698/PED.2016.02.02 -

下载:

下载: