Mechanism and Failure Mode of Tensile Strength Deterioration of Shikuosi Sandstone under Dry and Wet Cycling

-

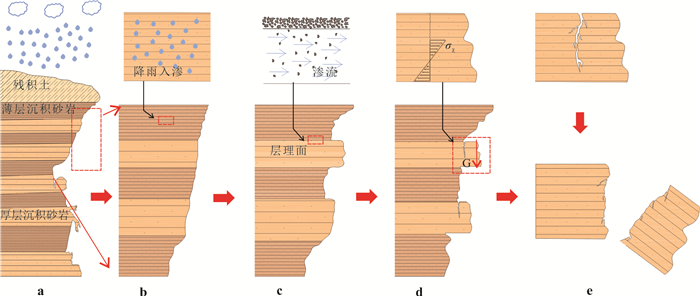

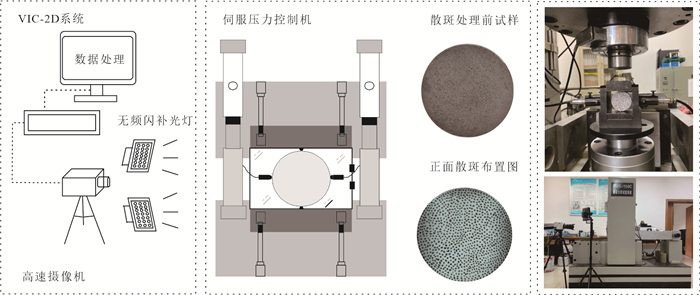

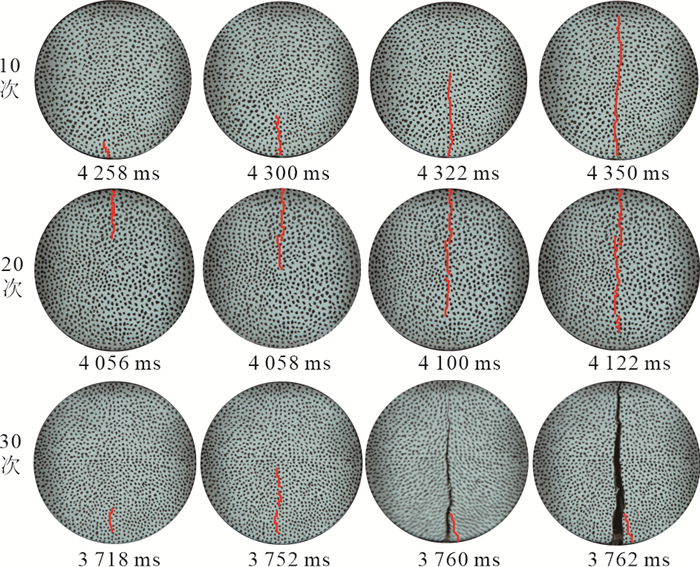

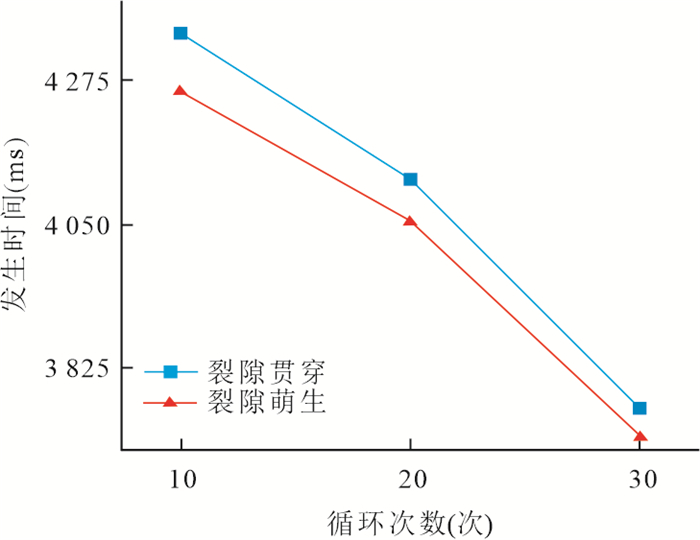

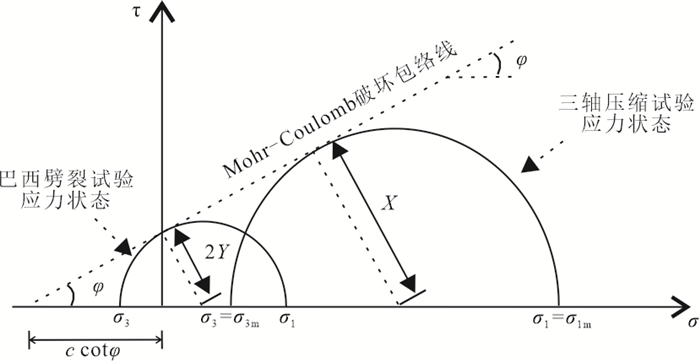

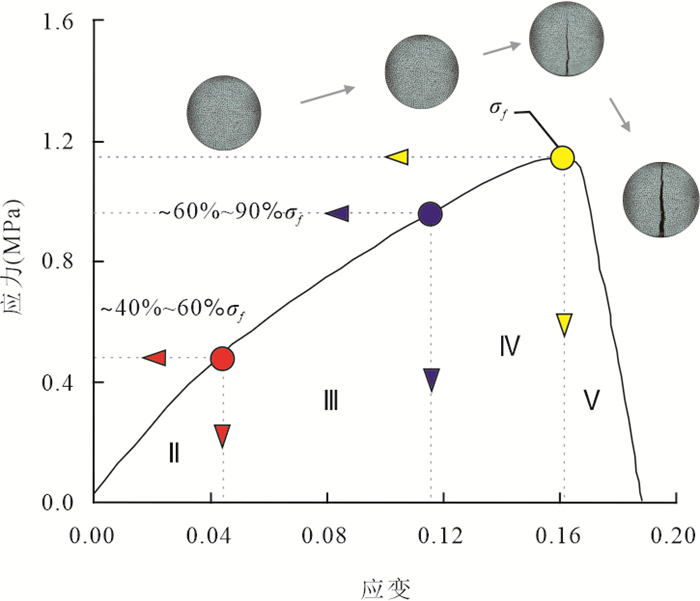

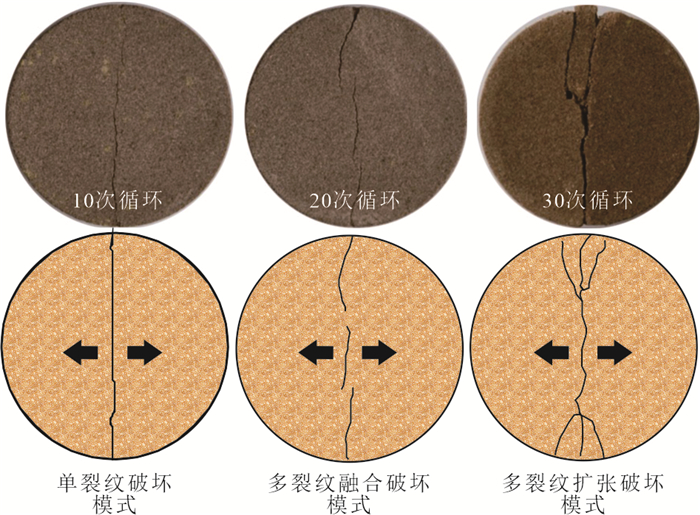

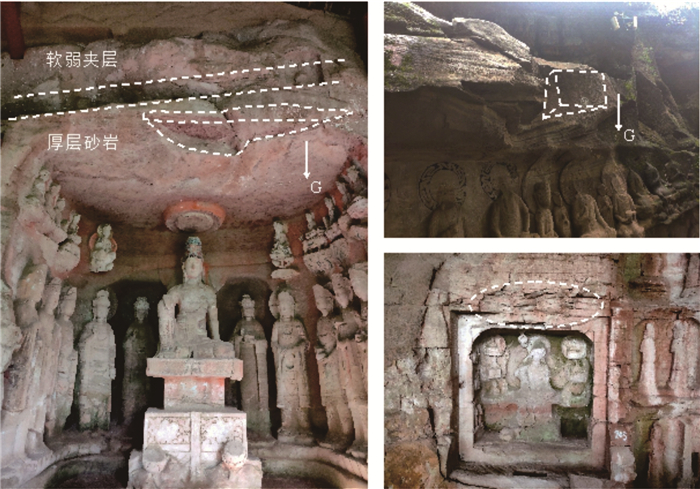

摘要: 干湿循环作用对石窟砂岩影响严重,造成了大量石窟砂岩的悬臂拉裂式破坏. 通过室内干湿循环试验、巴西劈裂试验以及应变场分析等方法,分析了不同干湿循环次数下试样的内摩擦角φ、粘聚力c、微观结构、以及应变场特征的变化规律. 研究发现随着干湿循环次数的增加,粘土矿物逐渐流失,结构变得松散,矿物颗粒间的胶结作用减弱,导致了砂岩粘聚力c的减小. 同时由于砂岩内部颗粒形状以及孔隙结构的变化改变了颗粒间的接触关系,导致了内摩擦角φ的减小,最终造成了其拉裂力学性质的劣化. 最后结合试样的破坏过程及裂纹展布总结出了不同干湿循环作用下石窟砂岩的两种破坏模式.Abstract: The dry-wet cycle has a serious impact on the grotto sandstone, causing a large number of cantilever cracking damages to the grottoes. Through indoor dry-wet cycle test, Brazil split test and strain field analysis methods, the strength and mechanical parameters of the sample under different numbers of dry-wet cycles are analyzed and studied. The internal friction angle φ, cohesive force c, microstructure, strain field characteristics The law of change. The study found that with the increase of the number of dry-wet cycles, clay minerals gradually lost and the structure became loose. The weakening of the cementation between mineral particles led to the decrease of the cohesive force c of sandstone. At the same time, due to the change of the particle shape and pore structure of the sandstone, the contact relationship between the particles was changed, which led to the reduction of the internal friction angle φ, and finally caused the deterioration of its tensile and fracture mechanical properties. Finally, combining the failure process and crack distribution of the sample, two failure modes of the grotto sandstone under different dry-wet cycles are summarized.

-

Key words:

- rock mechanics /

- wetting-drying cycles /

- grotto sandstone /

- tensile strength /

- deterioration mechanism

-

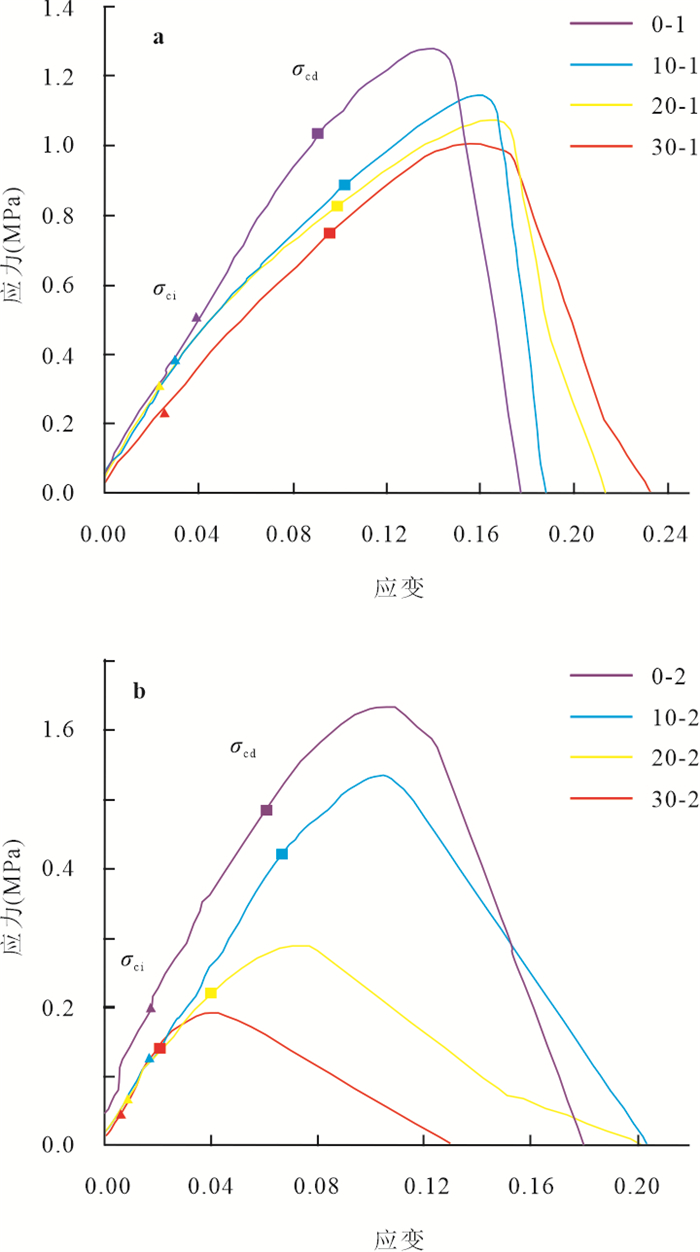

图 13 试样的应力应变曲线及裂纹起始应力$ {\mathit{\sigma }}_{\text{c}\text{i}} $和裂纹损伤应力$ {\mathit{\sigma }}_{\text{c}\text{d}} $

a. 干燥试样;b. 饱和试样

Fig. 13. The stress-strain curve of the sample and the initial crack stress $ {\mathit{\sigma }}_{\text{c}\text{i}} $ and the crack damage stress $ {\mathit{\sigma }}_{\text{c}\text{d}} $

表 1 试样矿物含量表(%)

Table 1. Sample mineral content table(%)

矿物 石英 钾长石 斜长石 方解石 粘土矿物 含量 36.0 6.0 28.3 12.0 11.4 表 2 试样参数

Table 2. Specimen parameters

循环次数 0次循环 10次循环 20次循环 30次循环 编号 0-1 0-2 10-1 10-2 20-1 20-2 30-1 30-2 直径(mm) 49.14 49.32 49.34 49.42 49.24 49.43 49.24 49.26 高(mm) 24.90 24.56 25.1 25.12 25.14 25.2 25.1 25.14 质量(g) 101.23 101.00 104.41 104.76 104.10 104.44 102.97 103.37 密度(g/cm3) 2.145 2.154 2.177 2.175 2.176 2.161 2.155 2.159 表 3 干燥试样的抗拉强度及三轴压缩强度

Table 3. Tensile strength and triaxial compressive strength of samples

循环次数 0次 10次 20次 30次 抗拉强度(MPa) 1.282 1.148 1.072 1.014 三轴压缩强度(MPa) 62.8 55.1 53.1 47.9 -

Deng, H. F., Li, J. L., Zhu, M., et al., 2012. Experimental Research on Strength Deterioration Rules of Sandstone under "Saturation-Air Dry" Circulation Function. Rock and Soil Mechanics, 33(11): 3306-3312(in Chinese with English abstract). Du, M. P., Pan, P. Z., Ji, W. W., et al., 2016. Time-Space Laws of Failure Process of Carbonaceous Shale in Brazilian Split Test. Rock and Soil Mechanics, 37(12): 3437-3446(in Chinese with English abstract). Feng, X. T., Lai, H. Z. H., 2000. Rock Fracturing Behaviors under Chemical Corrosion Part Ⅰ: Experimental Study. Chinese Journal of Rock Mechanics and Engineering, (4): 403-407(in Chinese with English abstract). Fu, Y., Wang, Z. J., Liu, X. R., et al., 2017. Meso Damage Evolution Characteristics and Macro Degradation of Sandstone under Wetting-Drying Cycles. Chinese Journal of Geotechnical Engineering, 39(9): 1653-1661(in Chinese with English abstract). Hale, P. A., Shakoor, A., 2003. A Laboratory Investigation of the Effects of Cyclic Heating and Cooling, Wetting and Drying, and Freezing and Thawing on the Compressive Strength of Selected Sandstones. Environmental and Engineering Geoscience, 9(2): 117-130. https://doi.org/10.2113/9.2.117 He, J., Wang, H., Eduardo Garzanti., 2020. Petrographic Analysis and Classification of Sand and Sandstone. Earth Science, 45(6): 2186-2198(in Chinese with English abstract). Li, Z., Zhang, J. K., Liu, D., et al., 2019. Experimental Study on Indoor Simulated Deterioration of Sandstone of XiaofowanStatues at Dazu Rock Carvings. Chinese Journal of Geotechnical Engineering, 41(8): 1513-1521(in Chinese with English abstract). Liu, S. J., Lan, H. X., Bao, H., et al., 2022. Classification System of Typical Engineering Geological Deformation and Failure Modes in Grottoes. Earth Science, 1-14(in Chinese with English abstract). Liu, X. R., Li, D. L., Zhang, L., 2016. Influence of Wetting-Drying Cycles on Mechanical Properties and Microstructure of Shaly Sandstone. Chinese Journal of Geotechnical Engineering, 38(7): 1291-1300(in Chinese with English abstract). Martin, C. D., Chandler, N. A., 1994. The Progressive Fracture of Lac Du Bonnet Granite. International Journal of Rock Mechanics & Mining Science & Geomechanics Abstracts, 31(6): 643-659. https://doi.org/10.1016/0148-9062(94)90005-1 Song, Y. J., Zhang, L. T., Ren, J. X., et al., 2019. Study on Damage Characteristics of Weak Cementation Sandstone under Drying-Wetting Cycles Based on Nuclear Magnetic resonance technique. Chinese Journal of Rock Mechanics and Engineering, 38(4): 825-831(in Chinese with English abstract). Sumner, P. D., Loubser, M. J., 2008. Experimental Sandstone Weathering Using Different Wetting and Drying Moisture Amplitudes. Earth Surface Processes and Landforms, 33(6): 985-990. https://doi.org/10.1002/esp.1586 Sun, J., Ling, J. M., Jia, G., et al., 2001. The Long-You Grottoes in the Western Land of Zhejiang Province from the View Point of Engineering Science. Chinese Journal of Rock Mechanics and Engineering, 20(1): 131-133 (in Chinese). Sun, Q., Zhang, Y. L., 2018. Combined Effects of Salt, Cyclic Wetting and Drying Cycles on the Physical and Mechanical Properties of Sandstone. Engineering Geology, 248(1): 70-79. https://doi.org/10.1016/j.enggeo.2018.11.009 Sun, W. J., Jin, A. B., Wang, S. L., et al., 2021. Study on Sandstone Split Mechanical Properties under High Temperature Based on the DIC Technology. Rock and Soil Mechanics, 42(2): 511-518(in Chinese with English abstract). Tang, L. S., Wang, S. J., 1999. Progress in the Study on Mechanical Effect of the Chemical Action of Water-Rock on Deformation and Failure of Rocks. Advances in Earth Sciences, 14(5): 433-439(in Chinese with English abstract). Tang, L. S., Wang, S. J., 2002. Analysis on Mechanism and Quantitative Methods of Chemical Damage in Water-Rock Interaction. Chinese Journal of Rock Mechanics and Engineering, 21(3): 314-319(in Chinese with English abstract). Wang, D. Y., Zhang, Z. X., Fu, L. C., et al., 1994. Analyses of Factors Affecting Destruction of Rockmass by Weathering in Baodingshan Grotto. Journal of Engineering Geology, 39(5): 912-926(in Chinese with English abstract). Wang, G. L., Wu, F. Q., Qi, S. W., 2012. Research on Failure Mechanisms for Cantilever and Tension Crack-Type Collapse. Rock and Soil Mechanics, 33(S2): 269-274(in Chinese with English abstract). Wang, H., Li, Y., Cao, S. G., et al., 2020. Brazilian Splitting Test Study on Crack Propagation Process and Macroscopic Failure Mode of Pre-Cracked Black Shale. Chinese Journal of Rock Mechanics and Engineering, 39(5): 912-926(in Chinese with English abstract). Wen, T., Zang, X., Sun, J. S., et al., 2021. Brittle Evaluation Based on Energy Evolution at Pre-Peak and Post-Peak Stage. Earth Science, 46(9): 3385-3396(in Chinese with English abstract). Xu, Y. C., Li, K. Q., Xie, X. F., et al., 2017. Grouting Reinforcement of Fractured Rock Mass Based on Damage Mechanics. Journal of Xi'an University of Science and Technology, 37(1): 26-31(in Chinese with English abstract). Yang, Z. F., Wang, S. J., Xu, B., et al., 2000. Analysis of the Engineering Geological Conditions of Longyou Stone Caves and Primary Study on the Protection Strategies. Journal of Engineering Geology, (3): 291-295(in Chinese with English abstract). Yuan, P., Ma, Q. Y., 2013. Split Hopkinson Pressure Bar Tests on Sandstone in Coalmine under Cyclic Wetting and Drying. Rock and Soil Mechanics, (9): 2557-2562(in Chinese with English abstract). Zhang, H. Q., Tannant, D. D., Jing, H. W., et al., 2015. Evolution of Cohesion and Friction Angle during Microfracture Accumulation in Rock. Natural Hazards, 77(1): 497-510. https://doi.org/10.1007/s11069-015-1592-2 Zhang, Z. H., Chen, X. C., Yao, H. Y., et al., 2021. Experimental Investigation on Tensile Strength of Jurassic Red-Bed Sandstone under the Conditions of Water Pressures and Wet-Dry Cycles. KSCE Journal of Civil Engineering, 25(7): 2713-2724. https://doi.org/10.1007/s12205-021-1404-z Zhao, N., Wang, L. G., Xi, Y. H., 2015. Experiment Study of Crack Propagation and Strain Evolution of Brazil Disc Mudstone Specimen. Journal of Experimental Mechanics, 30(6): 791-796(in Chinese with English abstract). Zhou, P. G., 1996. Engineering Geomechanics Research on the Interaction Between Groundwater and Rock-Soil Medium. Earth Sciene Frontiers, (2): 176. (in Chinese). 邓华锋, 李建林, 朱敏, 等, 2012. 饱水-风干循环作用下砂岩强度劣化规律试验研究. 岩土力学, 33(11): 3306-3312. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201211018.htm 杜梦萍, 潘鹏志, 纪维伟, 等, 2016. 炭质页岩巴西劈裂载荷下破坏过程的时空特征研究. 岩土力学, 37(12): 3437-3446. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201612012.htm 冯夏庭, 赖户政宏, 2000. 化学环境侵蚀下的岩石破裂特性——第一部分: 试验研究. 岩石力学与工程学报, (4): 403-407. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202401014.htm 傅晏, 王子娟, 刘新荣, 等, 2017. 干湿循环作用下砂岩细观损伤演化及宏观劣化研究. 岩土工程学报, 39(9): 1653-1661. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201709016.htm 何杰, 王华, Eduardo Garzanti, 2020. 砂岩(砂)的岩相分析和分类标准. 地球科学, 45(6): 2186-2198. doi: 10.3799/dqkx.2019.217 李震, 张景科, 刘盾, 等, 2019. 大足石刻小佛湾造像砂岩室内模拟劣化试验研究. 岩土工程学报, 41(8): 1513-1521. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201908019.htm 刘世杰, 兰恒星, 包含, 等, 2022. 石窟寺典型工程地质变形破坏模式及分类体系. 地球科学, : 1-14. doi: 10.3799/dqkx.2022.024 刘新荣, 李栋梁, 张梁, 等, 2016. 干湿循环对泥质砂岩力学特性及其微细观结构影响研究. 岩土工程学报, 38(7): 1291-1300. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201607017.htm 宋勇军, 张磊涛, 任建喜, 等, 2019. 基于核磁共振技术的弱胶结砂岩干湿循环损伤特性研究. 岩石力学与工程学报, 38(4): 825-831. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201904018.htm 孙钧, 凌建明, 贾岗, 等, 2001. 从工程科学角度看浙西大地的龙游石窟. 岩石力学与工程学报, 20(1): 131-133. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200101033.htm 孙文进, 金爱兵, 王树亮, 等, 2021. 基于DIC的高温砂岩劈裂力学特性研究. 岩土力学, 42(2): 511-518. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202111017.htm 汤连生, 王思敬, 1999. 水—岩化学作用对岩体变形破坏力学效应研究进展. 地球科学进展, 14(5): 433-439. https://www.cnki.com.cn/Article/CJFDTOTAL-DXJZ199905002.htm 汤连生, 王思敬, 2002. 岩石水化学损伤的机理及量化方法探讨. 岩石力学与工程学报, 21(3): 314-319. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200203003.htm 汪东云, 张赞勋, 付林森, 等, 1994. 宝顶山石窟岩体风化破坏的作用因素分析. 工程地质学报, (2): 54-65. https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ402.006.htm 王根龙, 伍法权, 祁生文, 2012. 悬臂-拉裂式崩塌破坏机制研究. 岩土力学, 33(S2): 269-274. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2012S2043.htm 王辉, 李勇, 曹树刚, 等, 2020. 含预制裂隙黑色页岩裂纹扩展过程及宏观破坏模式巴西劈裂试验研究. 岩石力学与工程学报, 39(5): 912-926. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202005006.htm 温韬, 张馨, 孙金山, 等, 2021. 基于峰前和峰后能量演化特征的岩石脆性评价. 地球科学, 46(9): 3385-3396. doi: 10.3799/dqkx.2020.342 许延春, 李昆奇, 谢小锋, 等, 2017. 裂隙岩体损伤的注浆加固效果试验. 西安科技大学学报, 37(1): 26-31. https://www.cnki.com.cn/Article/CJFDTOTAL-XKXB201701005.htm 杨志法, 王思敬, 许兵, 等, 2000. 龙游石窟群工程地质条件分析及保护对策初步研究. 工程地质学报, (3): 291-295. https://www.cnki.com.cn/Article/CJFDTOTAL-GCDZ200003006.htm 袁璞, 马芹永, 2013. 干湿循环条件下煤矿砂岩分离式霍普金森压杆试验研究. 岩土力学, (9): 2557-2562. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201309021.htm 赵娜, 王来贵, 习彦会, 2015. 巴西圆盘泥岩试件裂纹扩展及应变演化实验研究. 实验力学, 30(6): 791-796. https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX201506014.htm 周平根, 1996. 地下水与岩土介质相互作用的工程地质力学研究. 地学前缘, (2): 176. https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY602.007.htm -

下载:

下载: