Preparation Tests of High Flowing Soil from Subway Residue Soil in Yellow River Flooding Area

-

摘要:

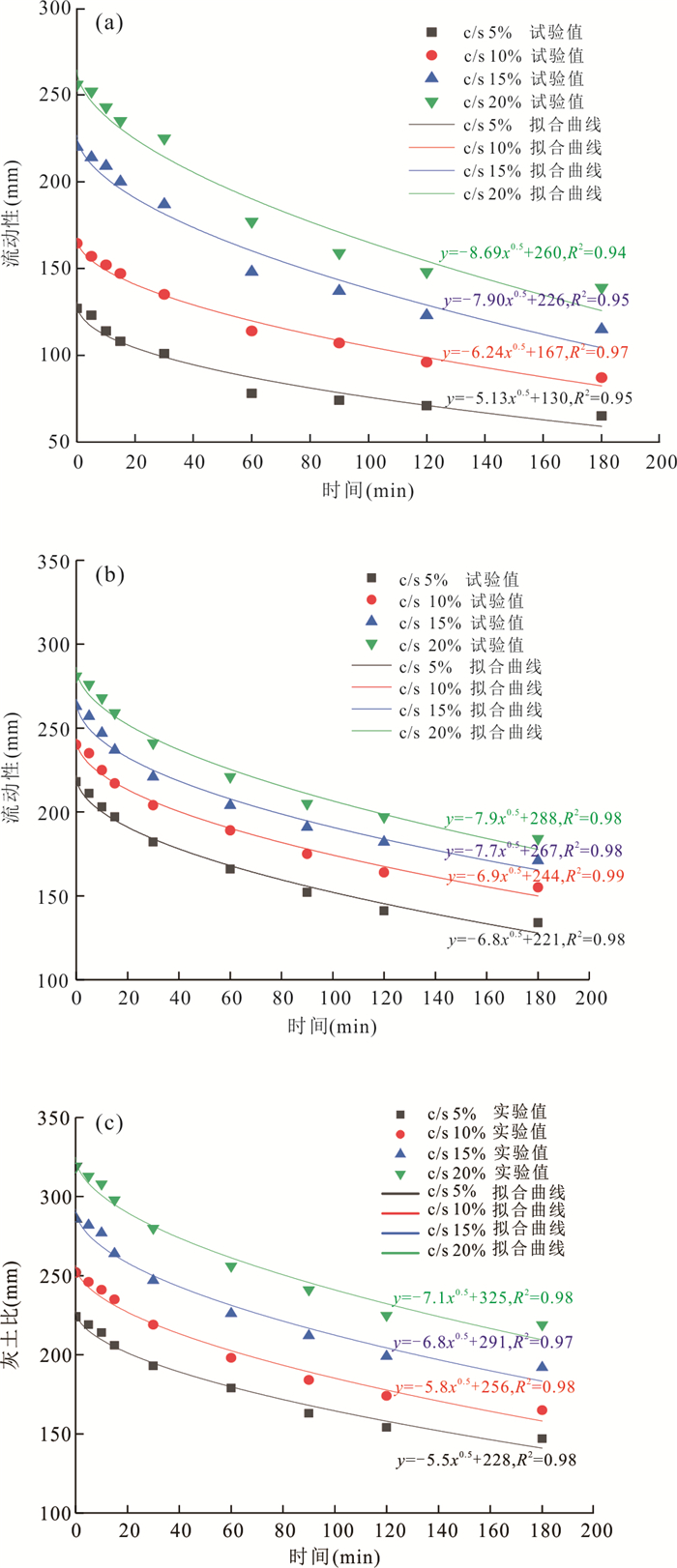

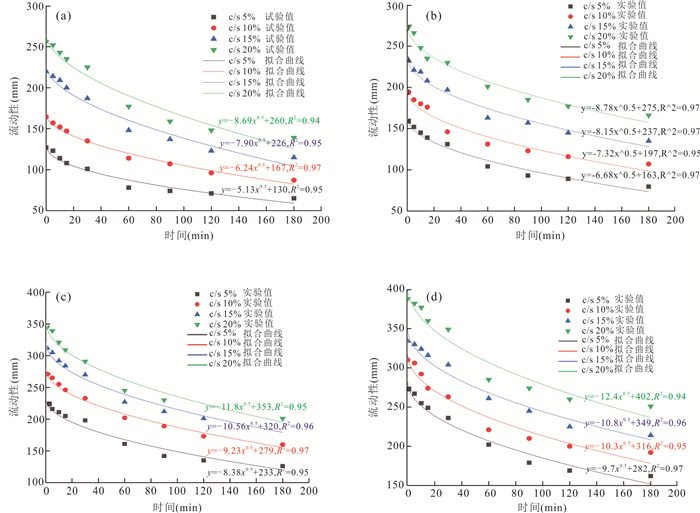

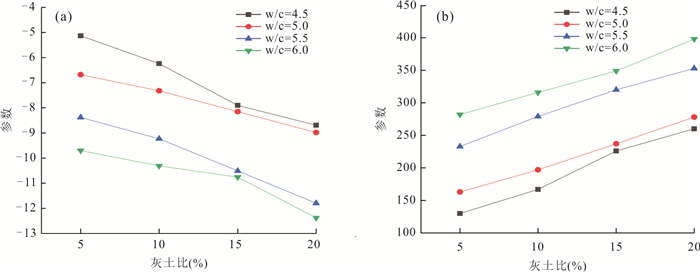

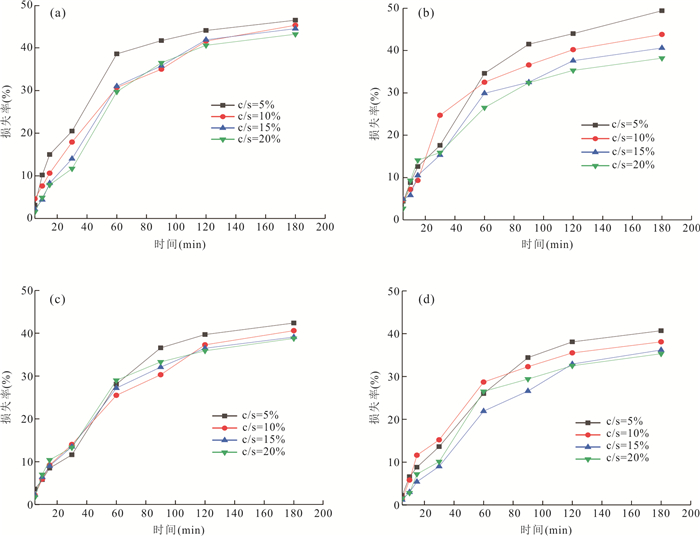

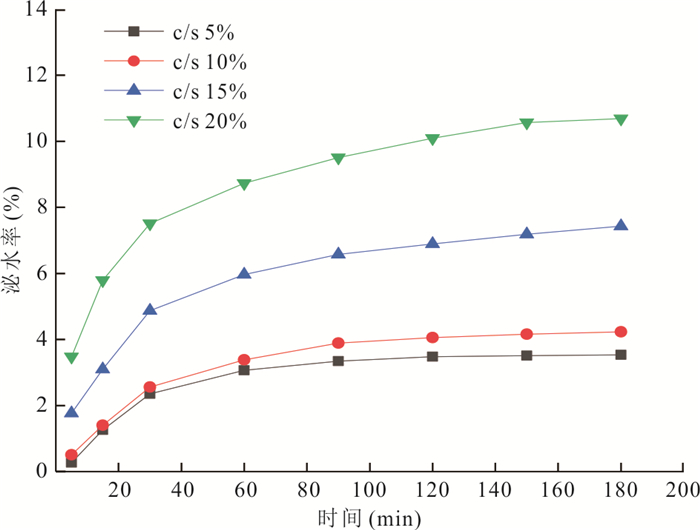

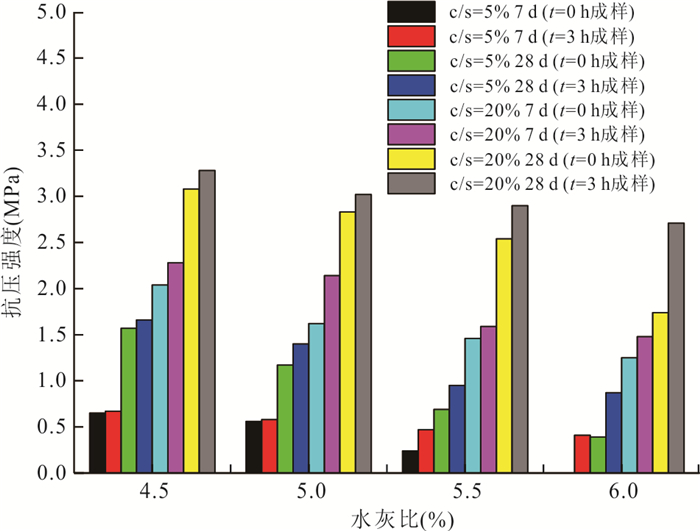

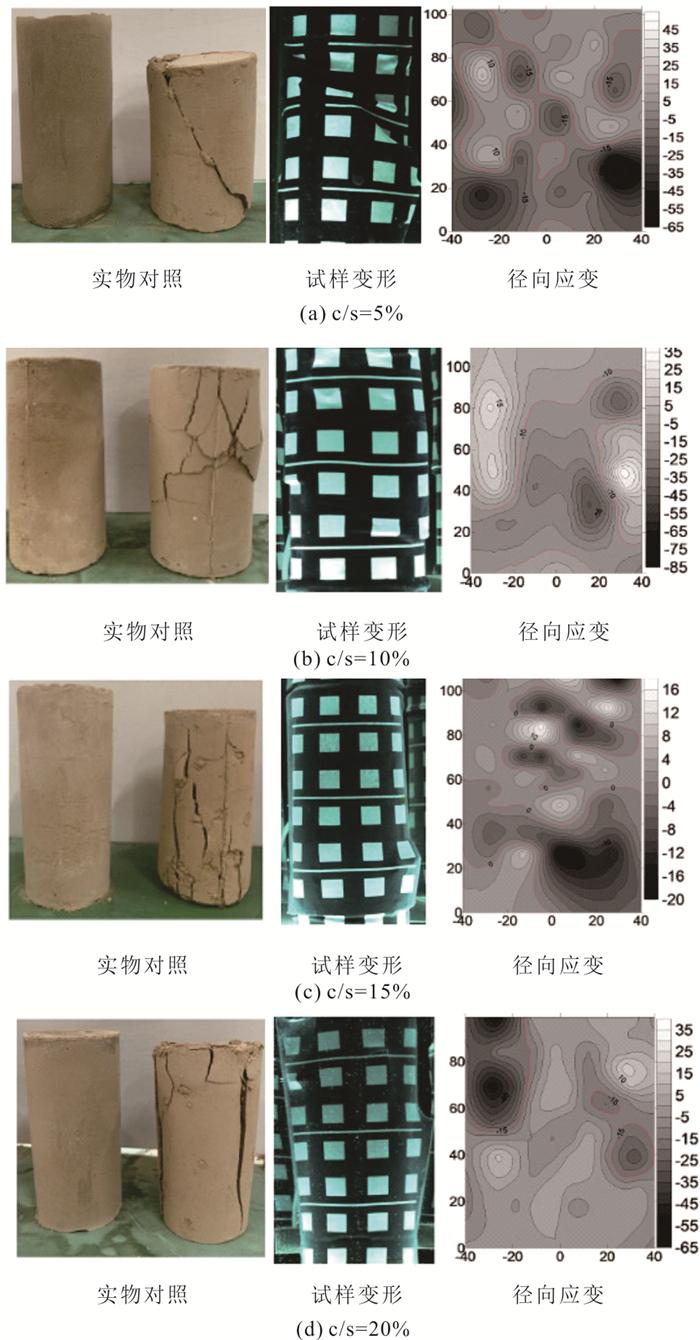

利用黄泛区地铁工程废弃土制备不同配比的高流动土,并对其工程特性及应用进行研究,提高工程废弃土的利用率,为实现工程低碳排放具有重要意义.取用郑州地区地铁工程废弃粉黏土、粉砂土作为原料,掺入一定比例的水泥和水,配制了24组不同土类、不同配合比、不同预拌时间等影响的流动土试样.利用流动性试验、泌水试验测试时间对流动土流动特性的影响,推荐了粉黏流动土流动性随时间变化经验公式.通过图像三轴仪,测试了粉黏流动土固化后的无侧限强度及变形特征,分析了不同破坏模式.试验结果表明,粉砂土流动土的流动性强于粉黏流动土,泡沫能增加流动土的流动性.大部分流动土在2小时内流动性能满足工程的要求,当需要增加预拌时间时,需要综合考虑强度和流动性需求.粉黏流动土试样剪切后有剪切破坏、压缩破坏、劈裂破坏等3种破坏模式,其受水泥掺量不同而改变.通过流动损失率、强度、变形等分析了该地区高流动土的工程应用控制指标和对策,对于指导该地区地铁废弃渣土的工程应用提供试验依据.

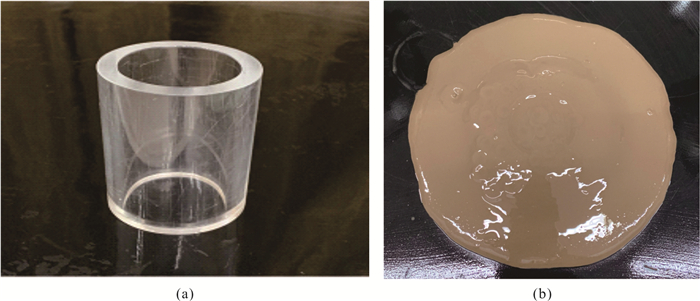

Abstract:The engineering behaviors of high flowing soil prepared from the subway residue soil were tested in this paper, which may greatly improve the utilized efficiency of the soil. The waste silty clay and silty sand were used in these tests mixing with different proportions of cement and water. Twenty-four groups of mixing soil considering the effect of soil type and mix proportion were prepared for the tests. The tests includes the fluidity measuring tests, bleeding tests and strength tests, which characterize the engineering behavior of these samples. It can be concluded that the low-strength sand soil shows a greater fluidity than that of the silty clay. The adding of foam can also improve its fluidity of the mixing soil. Most of the fluidity parameters prepared mixing soil can meet the engineering requirement within two hours. An empirical formula of fluidity was fitted from the test results of the mixing silty clay soil. The unconfined strength and deformation characteristics of solidified soil samples were also performed by digital image triaxial apparatus. The different failure modes were analyzed by comparing the original and damaged solidified soil samples. It can be concluded that the failure modes were represented by the shear failure, compression failure and splitting failure when the contents of curing agent are 5%, 10%, 15% and 20%, respectively. The flow loss rate, compressive strength and deformation model of the flowing soil were presented, from which the engineering application of preparing high flowing soil were recommended.

-

Key words:

- Yellow River flooding area /

- subway residue soil /

- liquidity /

- ready-mixed /

- high flowing soil /

- engineering geology

-

表 1 流动土配合比

Table 1. The mix proportions of flowing soil

试件编号 土类别 水灰比

w/c灰土比(%)

c/s配比质量(取2 kg土计算) 水泥g(mc) 干土g(m0) 土中水含量g(mw1) 需加水g(mw2) 1-1 粉黏土 4.5 5 90 1 796 204 200 1-2 10 180 1 796 204 604 1-3 15 269 1 796 204 1 008 1-4 20 359 1 796 204 1 412 2-1 粉黏土 5 5 90 1 796 204 245 2-2 10 180 1 796 204 694 2-3 15 269 1 796 204 1 143 2-4 20 359 1 796 204 1 592 2-5 粉砂土 5 5 95 1 908 92 385 2-6 10 191 1 908 92 862 2-7 15 286 1 908 92 1 339 2-8 20 382 1 908 92 1 816 2-9 泡沫土(泡沫掺入土质量的2%) 5 5 90 1 796 204 245 2-10 10 180 1 796 204 694 2-11 15 269 1 796 204 1 143 2-12 20 359 1 796 204 1 592 3-1 粉黏土 5.5 5 90 1 796 204 290 3-2 10 180 1 796 204 784 3-3 15 269 1 796 204 1 278 3-4 20 359 1 796 204 1 772 4-1 粉黏土 6 5 90 1 796 204 335 4-2 10 180 1 796 204 874 4-3 15 269 1 796 204 1 412 4-4 20 359 1 796 204 1951 -

Chen, R. H., Zhen, P. M., 2020. Analysis on Influencing Factors of Ready-Mixed Fluid Solidified Soil Based on Silty Clay. Chongqing Architecture, 19(9): 32-36(in Chinese with English abstract). doi: 10.3969/j.issn.1671-9107.2020.09.32 Dai, L. M., Niu, C. M., Pang, X. J., et al., 2020. Reservoir Characteristics and Forming Mechanisms of Lacustrine Mixed Sedimentary Rock of First and Second Members of Shahejie Formation in BZ27-A Structure, Huanghekou Sag. Earth Science, 45(10): 3797-3807(in Chinese with English abstract). Feng, L. P., Liao, S. M., Zhou, D. J., 2021. Soil Conditioning Techniques for Shield Tunneling in Argillaceous Siltstone Strata. Tunnel Construction, 41(Suppl. 2): 158-164(in Chinese with English abstract). Hao, T., Wang, S., Leng, F. G., 2020. Preparation of High Fluid Filling Materials by Using Subway Shield Muck. Bulletin of the Chinese Ceramic Society, 39(5): 1525-1532(in Chinese with English abstract). Li, M., Yan, S. H., Li, S., et al., 2022. Study on Structural Mechanical Behavior of Secondary Backfill of High Filled Open Cut Tunnel with Foamed Lightweight Soil. Journal of the China Railway Society, (2): 135-142(in Chinese with English abstract). doi: 10.3969/j.issn.1001-8360.2022.02.017 Liang, Z. S., Yang, C. Q., Gao, H. Y., et al., 2016. Experimental Study on Rapid Separation between Water and Slurry from Construction Engineering. Journal of Southeast University (Natural Science Edition), 46(2): 427-433(in Chinese with English abstract). Liu, X. D., 2018. Application of Ready-Mixed Fluid Stabilized Soil Technique in Foundation Trench Backfill Construction of Underground Comprehensive Pipe. Building Technology Development, 45(4): 61-62(in Chinese with English abstract). Puppala, A. J., Chittoori, B., Raavi, A., 2015. Flowability and Density Characteristics of Controlled Low-Strength Material Using Native High-Plasticity Clay. Journal of Materials in Civil Engineering, 27(1): 060140261. https://doi.org/10.1061/(asce)mt.1943-5533.0001127 Ren, L., Zhu, Y., Cui, T. L., 2021. Study on Protection Scheme of Shield Tunnel Passing through Railway Bridge Pile at a Short Distance. Earth Science, 46(6): 2278-2286(in Chinese with English abstract). Wang, X. R., Jiang, H. J., Zhu, K., et al., 2019. Research on Ground Settlement Laws of Urban Subway Tunnel Construction Process Based on Earth Pressure Shield. Earth Science, 44(12): 4293-4298(in Chinese with English abstract). Wei, J. J., Zhang, J. X., Wang, J. G., 2016. Properties of Flowable Backfill Materials Using Recycled Fine Aggregates of Brick and Concrete Waste. Journal of Civil, Architectural & Environmental Engineering, 38(3): 96-103(in Chinese with English abstract). Xi, Z. D., Hu, L. H., Zhang, S. X., et al., 2021. Soil Conditioning for Large-Diameter Shield Boring in Water-Rich Sandy Pebble Strata: A Case Study on a Shield-Bored Section of Chengdu Metro. Tunnel Construction, 41(1): 37-43(in Chinese with English abstract). doi: 10.3973/j.issn.2096-4498.2021.01.004 Yan, D. Y. S., Tang, I. Y., Lo, I. M. C., 2014. Development of Controlled Low-Strength Material Derived from Beneficial Reuse of Bottom Ash and Sediment for Green Construction. Construction and Building Materials, 64: 201-207. https://doi.org/10.1016/j.conbuildmat.2014.04.087 Ye, C. L., 2018. Study of Ground Conditioning Technology for Earth Pressure Balance (EPB) Shield Used in High Water Pressure and High Permeability Sandy Stratum. Tunnel Construction, 38(2): 300-307(in Chinese with English abstract). Yi, P. C., Chen, Z. M., Zhang, C. S., 2021. Residue Improvement Technology for EPB Shield Construction in Silty Clay Soil. Urban Mass Transit, 24(12): 177-181(in Chinese with English abstract). Yuan, H. Q., Zhu, D. Y., Zhang, H. Q., et al., 2020. Compression Characteristics of Foamed Lightweight Soil under Triaxial Stress. Bulletin of the Chinese Ceramic Society, 39(10): 3379-3385(in Chinese with English abstract). Zeng, C. N., Jin, N. N., Gu, H., et al, 2020. Analysis of Triaxial Shear Characteristics of Soybean Meal Based on Digital Image Measurement Technology. Transactions of the Chinese Society of Agricultural Engineering, 36(5): 310-317(in Chinese with English abstract). Zhang, J. X., Wang, J. G., Li, X. H., et al., 2018. Rapid-Hardening Controlled Low Strength Materials Made of Recycled Fine Aggregate from Construction and Demolition Waste. Construction and Building Materials, 173: 81-89. https://doi.org/10.1016/j.conbuildmat.2018.04.023 Zhang, X. G., 2018. Study on Long Spiral Drilled Premixed Fluid Solidified Soil Composite Foundation in Subcenter of Beijing. Building Technology Development, 45(2): 59-62(in Chinese with English abstract). Zhou, Y. X., Wang, J. Z., 2019. Principle of Ready-Mixed Solidified Soil and Its Prospects for Engineering Application. New Building Materials, 46(10): 117-120(in Chinese with English abstract). Zhu, H. Z., Yu, F. Q., Geng, J., et al., 2021. Strength and Volume Stability of Controlled Low-Strength Material Based on Titanium Gypsum. Bulletin of the Chinese Ceramic Society, 40(11): 3644-3653(in Chinese with English abstract). Zhu, W., Zhao, D., Fan, X. H., et al., 2021. Research on Application of Residue Soil-Based Flowable Fill. Journal of Hohai University (Natural Sciences), 49(2): 134-139(in Chinese with English abstract). Zhu, Y. X., Bian, Y., Min, F. L., et al., 2020. Improvement of Metro Shield Muck to Controlled Low-Strength Material. China Civil Engineering Journal, 53(Suppl. 1): 245-251(in Chinese with English abstract). 陈容华, 甄朋民, 2020. 基于粉质黏土的预拌流态固化土的影响因素分析. 重庆建筑, 19(9): 32-36. 代黎明, 牛成民, 庞小军, 等, 2020. 黄河口凹陷渤中27-A构造沙一二段湖相混积岩储层特征及成因. 地球科学, 45(10): 3797-3807. doi: 10.3799/dqkx.2020.088 冯利坡, 廖少明, 周德军, 2021. 泥质粉砂岩地层地铁盾构掘进渣土改良技术研究. 隧道建设(中英文), 41(增刊2): 158-164. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD2021S2020.htm 郝彤, 王帅, 冷发光, 2020. 利用地铁盾构渣土制备高流态充填材料. 硅酸盐通报, 39(5): 1525-1532. 李明, 严松宏, 李盛, 等, 2022. 采用泡沫轻质土对高填明洞二次回填的结构受力特性研究. 铁道学报, 44(2): 135-142. https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB202202017.htm 梁止水, 杨才千, 高海鹰, 等, 2016. 建筑工程废弃泥浆快速泥水分离试验研究. 东南大学学报(自然科学版), 46(2): 427-433. https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201602031.htm 刘旭东, 2018. 预拌流态固化土技术在地下综合管廊基槽回填工程中的应用. 建筑技术开发, 45(4): 61-62. https://www.cnki.com.cn/Article/CJFDTOTAL-JZKF201804037.htm 任磊, 朱颖, 崔天麟, 2021. 盾构超近距离侧穿铁路桥桩保护方案探讨. 地球科学, 46(6): 2278-2286. doi: 10.3799/dqkx.2021.041 王晓睿, 姜洪建, 朱坤, 等, 2019. 基于土压盾构的城市地铁隧道构筑过程地表沉降规律. 地球科学, 44(12): 4293-4298. doi: 10.3799/dqkx.2019.269 魏建军, 张金喜, 王建刚, 2016. 建筑垃圾细料生产流动化回填材料的性能. 土木建筑与环境工程, 38(3): 96-103. https://www.cnki.com.cn/Article/CJFDTOTAL-JIAN201603014.htm 葸振东, 胡林浩, 张书香, 等, 2021. 富水砂卵石地层大直径盾构渣土改良试验研究——以成都地铁17号线明九区间2#风井-九江北站盾构工程为例. 隧道建设(中英文), 41(1): 37-43. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD202101004.htm 叶晨立, 2018. 高水压高渗透砂性地层土压平衡盾构施工渣土改良技术研究. 隧道建设(中英文), 38(2): 300-307. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201802023.htm 易鹏程, 陈志敏, 张常书, 2021. 粉质黏土层土压平衡盾构施工中的渣土改良技术. 城市轨道交通研究, 24(12): 177-181. https://www.cnki.com.cn/Article/CJFDTOTAL-GDJT202112039.htm 袁化强, 朱登元, 张宏庆, 等, 2020. 三轴应力条件下泡沫轻质土压缩特性. 硅酸盐通报, 39(10): 3379-3385. 曾长女, 金南南, 谷贺, 等, 2020. 基于数字图像测量技术的豆粕剪切变形特性. 农业工程学报, 36(5): 310-317. 张旭光, 2018. 北京城市副中心长螺旋压灌预拌流态固化土复合地基研究. 建筑技术开发, 45(2): 59-62. https://www.cnki.com.cn/Article/CJFDTOTAL-JZKF201802034.htm 周永祥, 王继忠, 2019. 预拌固化土的原理及工程应用前景. 新型建筑材料, 46(10): 117-120. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201910027.htm 朱浩泽, 于峰泉, 耿健, 等, 2021. 钛石膏基可控低强度材料强度及体积稳定性研究. 硅酸盐通报, 40(11): 3644-3653. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202111014.htm 朱伟, 赵笛, 范惜辉, 等, 2021. 渣土改良为流动化回填土的应用. 河海大学学报(自然科学版), 49(2): 134-139. https://www.cnki.com.cn/Article/CJFDTOTAL-HHDX202102006.htm 朱瑜星, 卞怡, 闵凡路, 等, 2020. 地铁盾构渣土改良为流动化土进行应用试验研究. 土木工程学报, 53(增刊1): 245-251. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC2020S1039.htm -

下载:

下载: