Thermodynamic Performance of Phase Change Mortar Based on Shape-Stabilized Phase Change Material

-

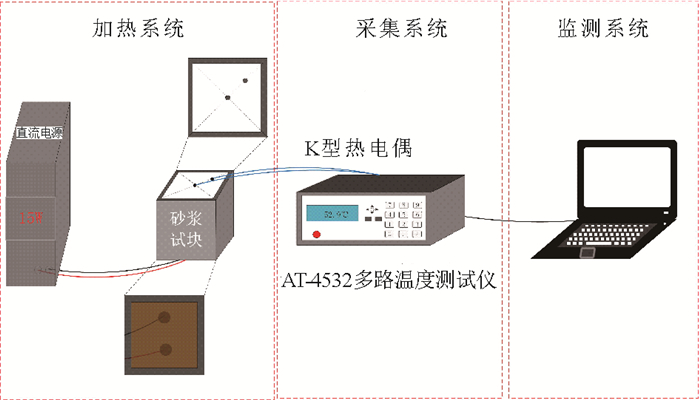

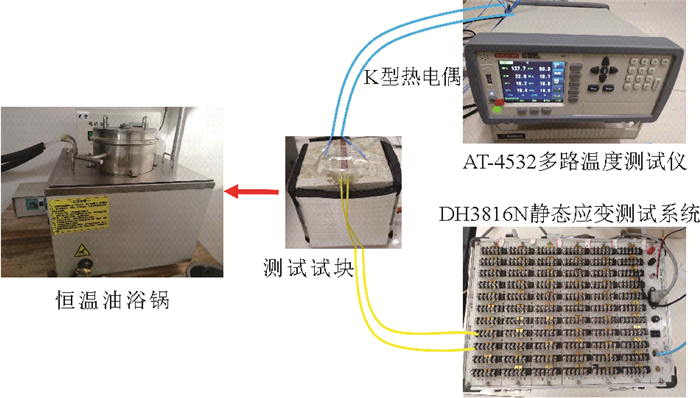

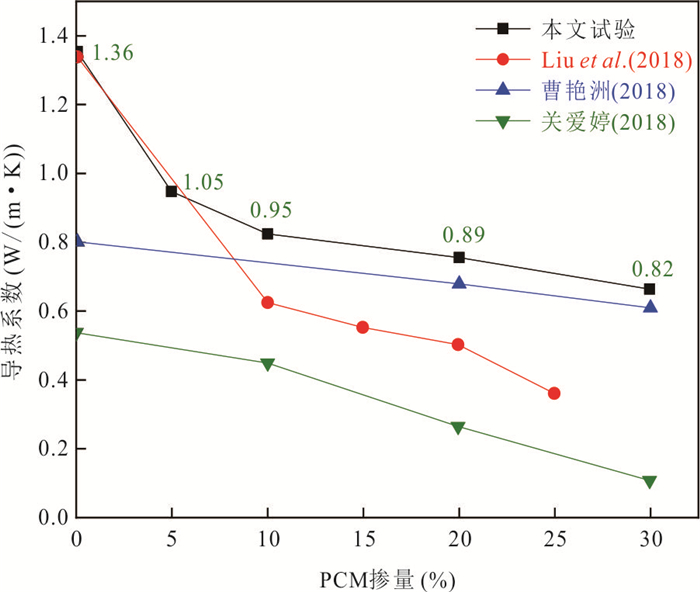

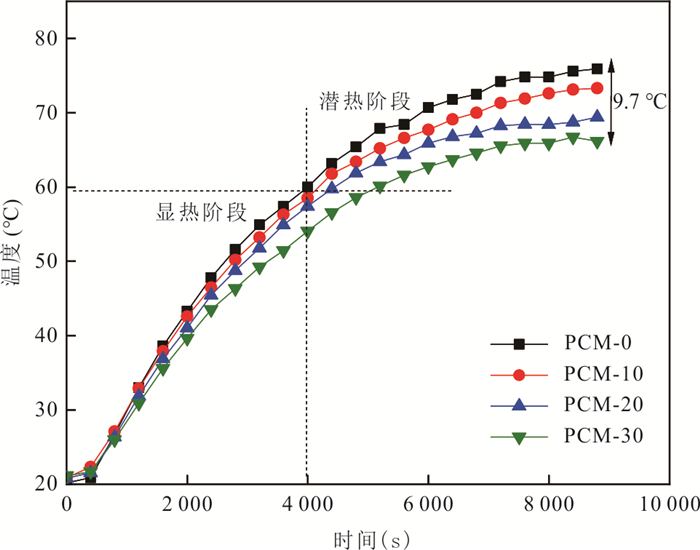

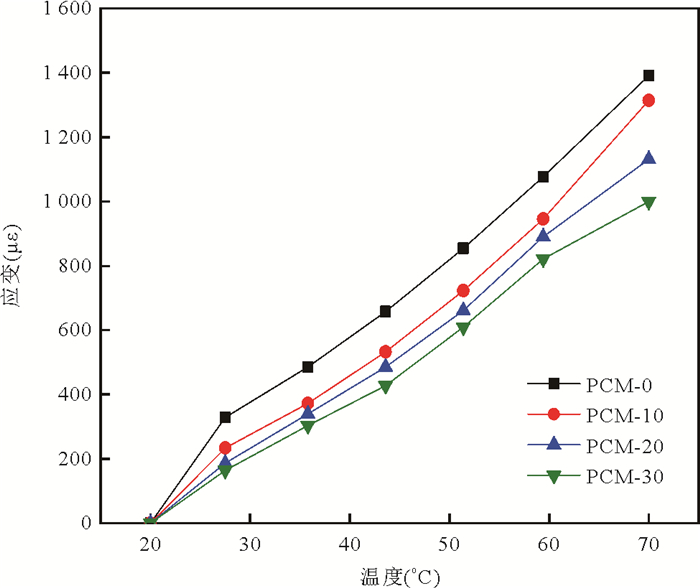

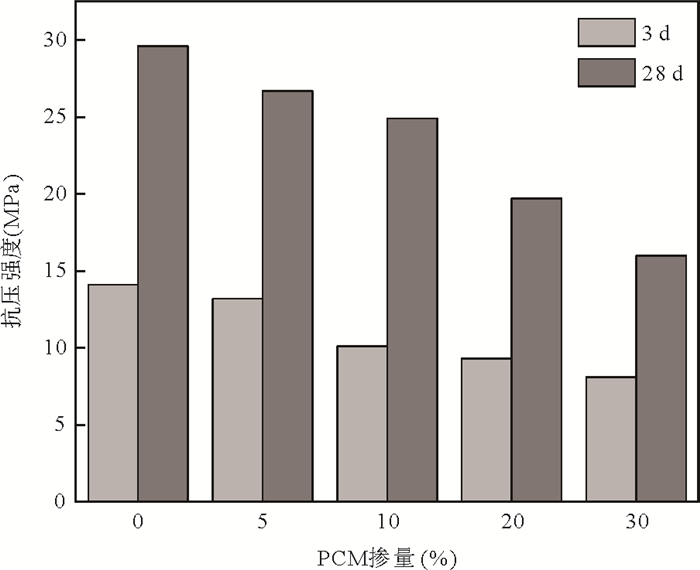

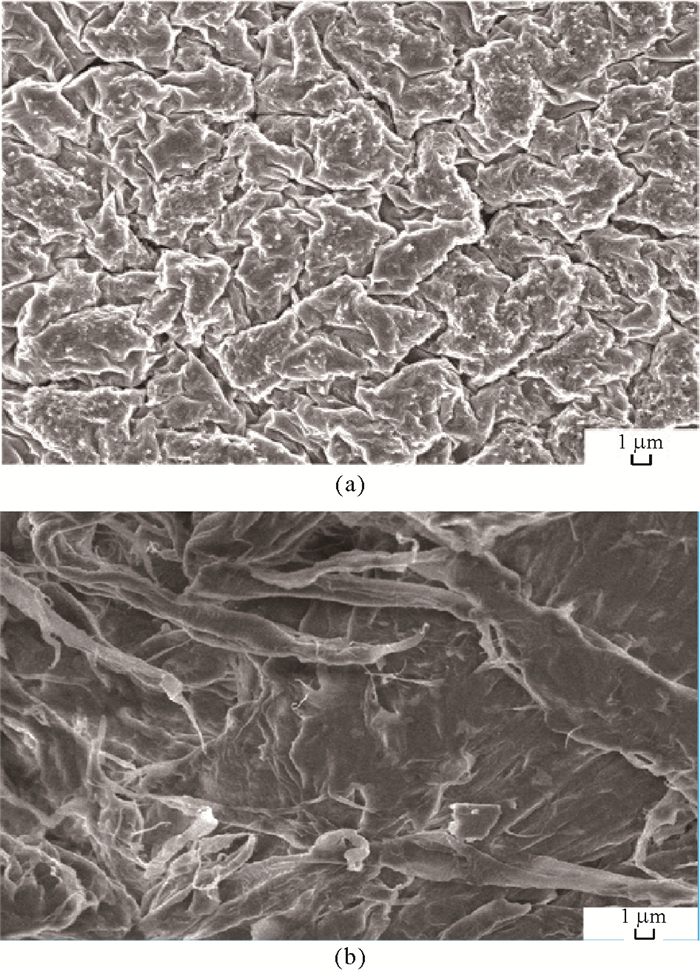

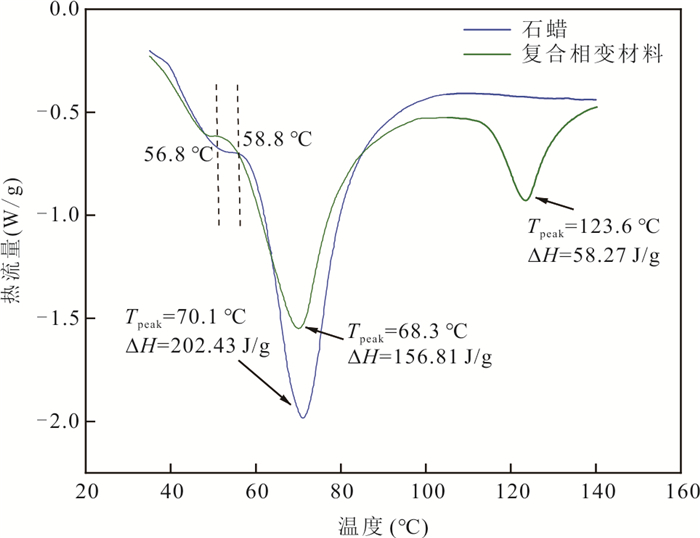

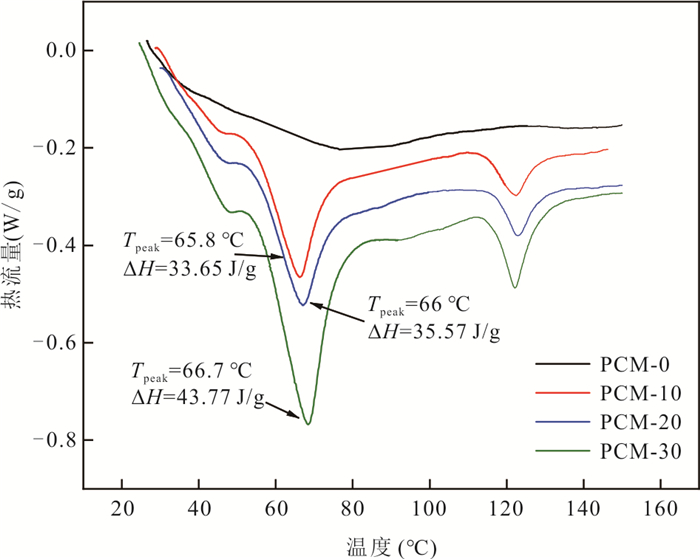

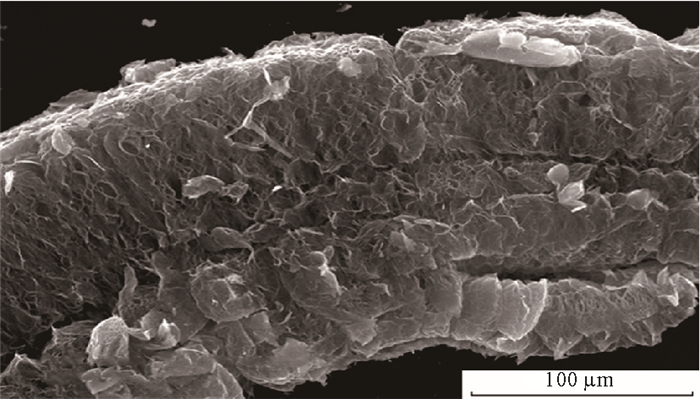

摘要: 普通砂浆受温度差异影响时,常常会产生温度变形、温度应力和温度裂缝,而现有相变砂浆的低热导率易导致相变不充分、储能效率低等问题,导致其自我调温能力低,也难以更好地控制由温度引起的变形、应力及裂缝.采用石蜡基相变材料制备储能型砂浆,并通过优选导热增强剂的比表面积、厚度等材料物理参数,从材料本身来提高相变基体热导率和相变砂浆储能速率,从而提升其自调温性能.设计并搭建了材料热性能测试平台,测试相变砂浆的蓄热和热应变发展规律.结果表明,相变材料掺量30%的砂浆试块上表面温度比普通砂浆块温度降低9.7 ℃,热应变降低27.54%,表明该相变材料提高了蓄热能力并显著提升了砂浆的温度自调控性能.Abstract: Ordinary mortar often produces thermal deformation and cracks when it is applied. However, the low thermal conductivity of the existing phase change mortar easily leads to insufficient phase change and low energy storage efficiency, resulting in low thermal adaptability. Thus, it cannot effectively control the development of deformation, stress and fracture induced by temperature change. In this paper, paraffin-based phase change materials are used to prepare energy storage mortar, and by optimizing the three-dimensional microscopic parameters such as the specific surface area and thickness of the thermal conductivity enhancer, the focus is on improving the thermal conductivity of the phase change matrix and the energy storage rate of the phase change mortar, thereby improving its thermal adaptability. A thermal test platform was built to test its thermal performance including the energy storage and the thermal strain development with time. It is concluded that when the phase change matrix material was mixed with 30%, the surface temperature of the mortar block was lower by 9.7 ℃ than that of the ordinary mortar block, and the thermal strain was reduced by 27.54%, indicating that the phase change material improved the heat storage efficiency and significantly improved its thermal properties of self-controlled temperature.

-

表 1 相变砂浆配比(kg/m3)

Table 1. Mix proportions of phase change mortar (kg/m3)

材料 PCM-0 PCM-5 PCM-10 PCM-20 PCM-30 水泥 500 500 500 500 500 水 300 300 300 300 300 砂 1 427.58 1 359.60 1 297.80 1 189.65 1 098.14 PCM 0 19.06 36.39 66.71 111.89 W/C 0.6 0.6 0.6 0.6 0.6 -

Cao, Y. Z., 2018. Preparation and Performance Optimization of Cement-Based Phase Change Thermal Storage Mortar (Dissertation). Xi'an University of Technology, Xi'an(in Chinese with English abstract). Djamai, Z. I., Salvatore, F., Larbi, A. S., et al., 2019. Multiphysics Analysis of Effects of Encapsulated Phase Change Materials (PCMS) in Cement Mortars. Cement and Concrete Research, 119: 51-63. https://doi.org/10.1016/j.cemconres.2019.02.002 Du, H. X., Wu, Z. X., Du, F., 2022. Effect of Polypropylene Fiber and Steel Bar on Thermal Strain of C60 High Performance Concrete Slab at High Temperature. Journal of Building Materials, 25(2): 142-149(in Chinese with English abstract). Guan, A. T., 2018. Study on Preparation and Properties of New Phase Change Temperature Control Materials (Dissertation). Dalian Jiaotong University, Dalian(in Chinese with English abstract). Guardia, C., Barluenga, G., Palomar, I., et al., 2019. Thermal Enhanced Cement-Lime Mortars with Phase Change Materials (PCM), Lightweight Aggregate and Cellulose Fibers. Construction and Building Materials, 221: 586-594. https://doi.org/10.1016/j.conbuildmat.2019.06.098 Guo, J. W., Jiang, Y. Q., Wang, Y., et al., 2020. Thermal Storage and Thermal Management Properties of a Novel Ventilated Mortar Block Integrated with Phase Change Material for Floor Heating: An Experimental Study. Energy Conversion and Management, 205: 112288. https://doi.org/10.1016/j.enconman.2019.112288 Kheradmand, M., Vicente, R., Azenha, M., et al., 2019. Influence of the Incorporation of Phase Change Materials on Temperature Development in Mortar at Early Ages: Experiments and Numerical Simulation. Construction and Building Materials, 225: 1036-1051. https://doi.org/10.1016/j.conbuildmat.2019.08.028 Kong, D. Y., Pan, L. S., Zhan, S. L., et al., 2016. Preparation and Properties of Phase Change Ceramisite Loaded with Inorganic Salt Hydrate. Journal of the Chinese Ceramic Society, 44(7): 1051-1058(in Chinese with English abstract). Kong, S. Y., See, Z. H., Lee, C. L., et al., 2019. Thermal and Mechanical Properties of Mortar Incorporated with Paraffin/Palm Oil Fuel Ash Composite. Journal of Building Engineering, 26: 100923. https://doi.org/10.1016/j.jobe.2019.100923 Lecompte, T., Le Bideau, P., Glouannec, P., et al., 2015. Mechanical and Thermo-Physical Behaviour of Concretes and Mortars Containing Phase Change Material. Energy and Buildings, 94: 52-60. https://doi.org/10.1016/j.enbuild.2015.02.044 Li, W. W., Cheng, W. L., Xie, B., et al., 2017. Thermal Sensitive Flexible Phase Change Materials with High Thermal Conductivity for Thermal Energy Storage. Energy Conversion and Management, 149: 1-12. https://doi.org/10.1016/j.enconman.2017.07.019 Liu, F. L., Zhu, J. Q., Ma, B. G., et al., 2016. Research Progress on Preparation and Application of Gypsum Phase Change Wallboard in Building Wall. Journal of the Chinese Ceramic Society, 44(8): 1178-1191(in Chinese with English abstract). Liu, Y. S., Xu, E. T., Xie, M. J., et al., 2018. Use of Calcium Silicate-Coated Paraffin/Expanded Perlite Materials to Improve the Thermal Performance of Cement Mortar. Construction and Building Materials, 189: 218-226. https://doi.org/10.1016/j.conbuildmat.2018.08.213 Ma, J. L., Li, Q., Chen, X. R., 2022. Analysis of the Advantages of Carbon Neutral Geological Energy Storage in Hydraulically Connected Reservoirs. Earth Science (in Chinese with English abstract)(in press). Ren, J. W., Wang, T., Chen, Y. L., et al., 2020. Research Status and Application Potential of CO2 Mineralization. Earth Science, 45(7): 2413-2425(in Chinese with English abstract). Sang, G. C., Fan, M., Cui, X. L., et al., 2019. Thermal and Mechanical Properties of Phase-Change Thermal Energy Storage Mortar Based on Compression Forming Method. Journal of Building Materials, 22(5): 693-699(in Chinese with English abstract). Shi, J. Y., Tan, J. X., Liu, B. J., et al., 2020. Thermal and Mechanical Properties of Thermal Energy Storage Lightweight Aggregate Mortar Incorporated with Phase Change Material. Journal of Energy Storage, 32: 101719. https://doi.org/10.1016/j.est.2020.101719 Wang, X. R., Liu, X., Zhang, X., et al., 2023. Vibration Response Caused by Silt Layer in Underground Subway under Small Radius Curve Tunnel. Earth Science, 48(6): 2415-2426(in Chinese with English abstract). Xiao, L. G., Song, S. A., Gao, S. Z., 2014. A Study of Preparation and Performance of the PCMs of the CA-LA Swelling Vitrified Beads. Proceedings of the 2015 International Conference on Material Science and Applications. Atlantis Press, Paris, France. https://doi.org/10.2991/icmsa-15.2015.133 Yang, J., Meng, D., Wang, A. Q., et al., 2020. Improvement of Thermal Insulation Performance of Building Envelope with Phase Change Mortar. New Building Materials, 47(1): 104-107(in Chinese with English abstract). Yang, J., Qi, G. Q., Liu, Y., et al., 2016. Hybrid Graphene Aerogels/Phase Change Material Composites: Thermal Conductivity, Shape-Stabilization and Light-to-Thermal Energy Storage. Carbon, 100: 693-702. https://doi.org/10.1016/j.carbon.2016.01.063 Zhang, N., Yuan, Y. P., Yuan, Y. G., et al., 2014. Effect of Carbon Nanotubes on the Thermal Behavior of Palmitic-Stearic Acid Eutectic Mixtures as Phase Change Materials for Energy Storage. Solar Energy, 110: 64-70. https://doi.org/10.1016/j.solener.2014.09.003 曹艳洲, 2018. 水泥基相变储能砂浆的制备及性能优化(硕士学位论文). 西安: 西安理工大学. 杜红秀, 吴振戌, 杜帆, 2022. PP纤维和钢筋对高温下C60HPC板热应变的影响. 建筑材料学报, 25(2): 142-149. 关爱婷, 2018. 新型相变控温材料的制备及其性能研究(硕士学位论文). 大连: 大连交通大学. 孔德玉, 潘罗晟, 詹树林, 等, 2016. 无机水合盐相变陶粒的制备与性能. 硅酸盐学报, 44(7): 1051-1058. 刘凤利, 朱教群, 马保国, 等, 2016. 相变石膏板制备及其在建筑墙体中应用的研究进展. 硅酸盐学报, 44(8): 1178-1191. 马建力, 李琦, 陈祥荣, 2022. 利用水力连通储层进行地质储能的优势分析. 地球科学(待刊). 任京伟, 王涛, 陈雨雷, 等, 2020. CO2矿化研究现状及应用潜力. 地球科学, 45(7): 2413-2425. doi: 10.3799/dqkx.2020.027 桑国臣, 樊敏, 崔晓玲, 等, 2019. 压力成型相变储能砂浆的热性能与力学性能. 建筑材料学报, 22(5): 693-699. 王晓睿, 刘旭, 张昕, 等, 2023. 小半径曲线隧道下地铁运行对粉砂土层引起的振动响应规律. 地球科学, 48(6): 2415-2426. doi: 10.3799/dqkx.2023.063 杨籍, 孟多, 王安琪, 等, 2020. 相变控温砂浆用于改善建筑围护结构保温性能的研究. 新型建筑材料, 47(1): 104-107. -

下载:

下载: